| –

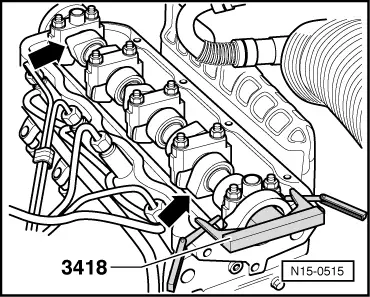

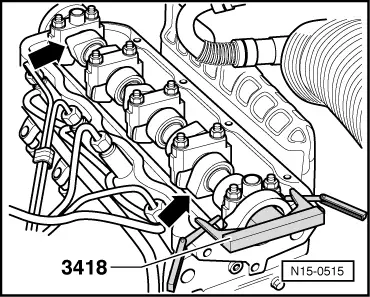

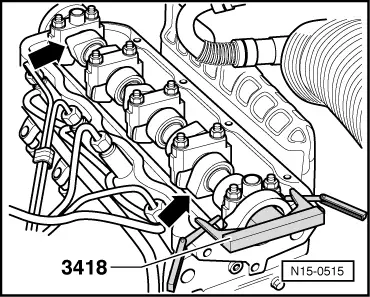

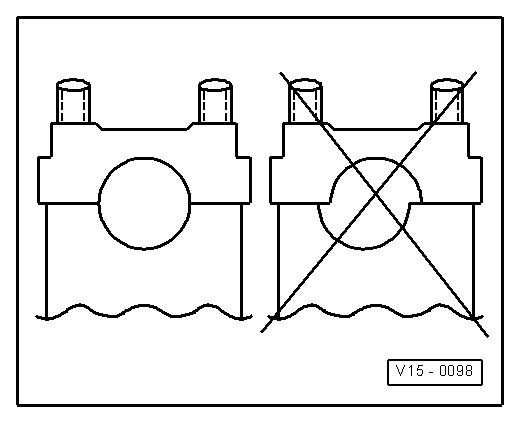

| Lock command shaft as shown with command shaft rule 3418. |

| –

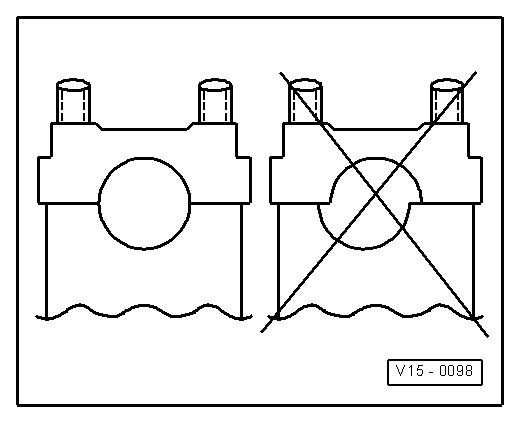

| Calculate adjusting rule average as follows: Turn locked command shaft so that rule end touches head. On the other adjusting rule end measure space with a gauge. Place gauge with half of space measure between adjusting rule and head. Turn command shaft until adjusting rule touches gauge. Insert another gauge with same measure in the other end between rule and head. |

Note | Command shaft may also be locked with command shaft rule -T10098-. |

| When indented belt is installed and distribution timings are adjusted → Chapter, remove, install and adjust indented belt. |

| –

| Remove mechanical distribution upper cover, head cover and vacuum pump. |

Note | After installing new hydraulic taps, engine may not be turned on for about 30 minutes. Hydraulic compensation elements must seat (otherwise, valves hit pistons). |

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note