Polo Mk4

| Pistons and rods - disasemble and assemble |

| 1 - | Segment rings |

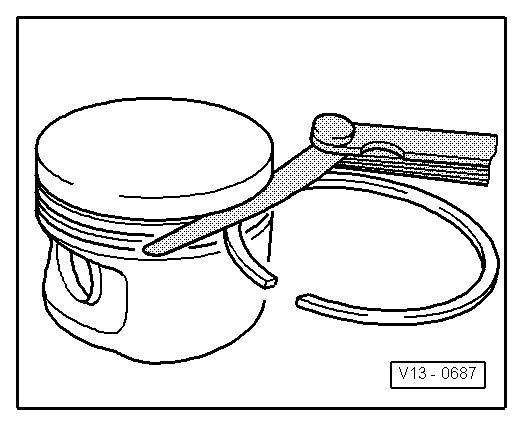

| q | Displace opening in 120 ° |

| q | Remove and install with ring plier |

| q | Reference “TOP” turned to piston head |

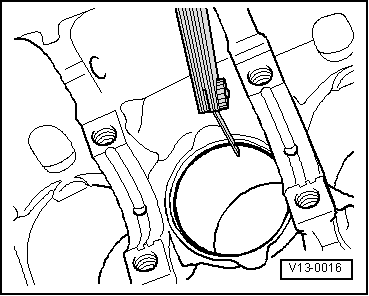

| q | Check opening between points → Fig. |

| q | Check ring play on piston groove → Fig. |

| 2 - | Piston |

| q | With combustion chamber |

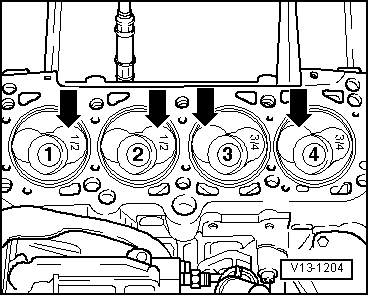

| q | Mark assembly position and correspondence to cylinder |

| q | Piston/cylinder installation position → Fig. |

| q | -Arrow- on piston head points to the belt pulley side |

| q | Install rings |

| q | Replace piston in case it is cracked |

| q | Check piston position on upper part → Chapter. |

| 3 - | Piston pin |

| q | In case of blocking, heat piston to 60°C |

| q | Remove and Drift -VW 222A- |

| 4 - | Block |

| 5 - | Rod |

| q | Mark position to cylinder -A- |

| q | Installation position: Markings -B- point to belt pulley side |

| q | Replace only in sets |

| 6 - | Caps |

| q | Pay attention to installation position |

| q | Pay attention to finishing: upper cap (towards piston) made of a more wear-resistant material Identification characteristic: black lining on sliding surface, in separation area |

| q | Do not invert caps used |

| q | Place caps centralized |

| q | Ensure proper seating on retaining slots |

| q | Axial play wear limit: 0.37 mm |

| q | Measure radial play with “Plastigage”: wear limit: 0.08 mm Do not turn crankshaft during measurement of radial play |

| 7 - | Engine block |

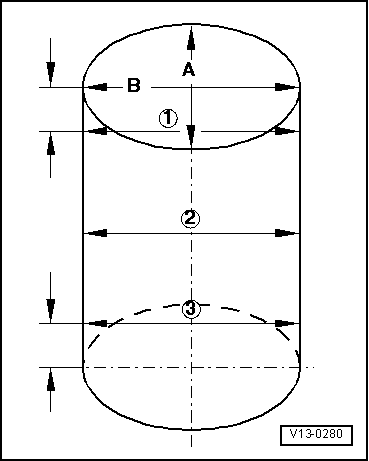

| q | Check cylinder diameter → Fig. |

| q | Piston and cylinder measurement → Chapter. |

| 8 - | Rod cap |

| q | Pay attention to installation position |

| q | Due to separation process (breaking) of rods, cap only seats in one position and matches only the pertaining rod |

| 9 - | Oil ejector |

| q | For piston cooling |

| 10 - | 25 Nm |

| q | Install without sealing |

| 11 - | Rod screw 30 Nm +90 ° |

| q | Replace |

| q | Lubrificate thread and support surface |

| q | Measure radial play with a used screw |

| Piston ring Measures in mm | New | Wear limit |

| 1. Compression ring | 0,20...0,40 | 1,0 |

| 2. Compression ring | 0.20...0.40 | 1.0 |

| Oil scraper ring | 0.25...0.50 | 1.0 |

|

|

| Piston ring Measures in mm | New | Wear limit |

| 1. Compression ring | 0.06...0.09 | 0.25 |

| 2. Compression ring | 0.05...0.08 | 0.25 |

| Oil scraper ring | 0.03...0.06 | 0.15 |

Note

Note

|

|

Note

Note

|

|