| –

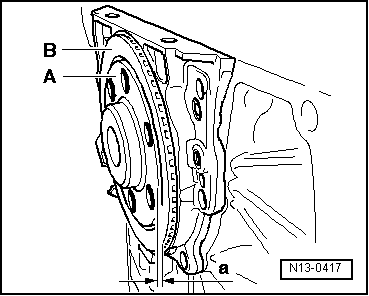

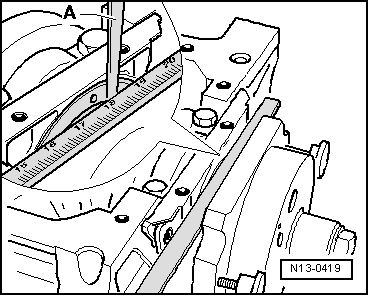

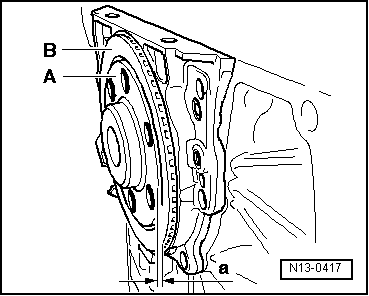

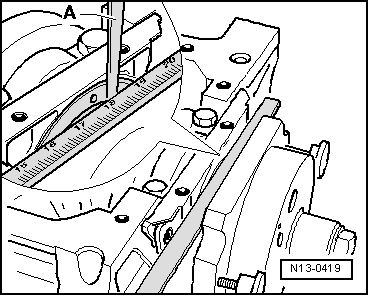

| Measure with razor caliper -A- the distance -a- between gauge rod and rotor. |

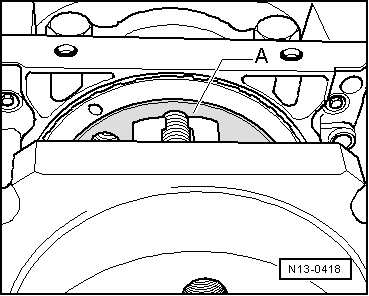

| If distance -a- is very small: |

| If distance is reached -a-: |

| –

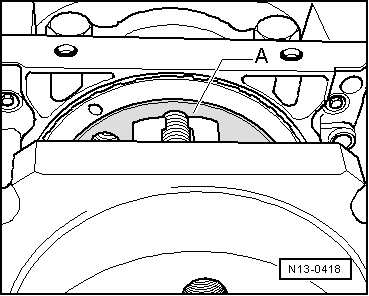

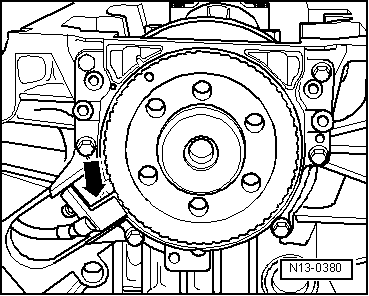

| Remove assembly device. |

| –

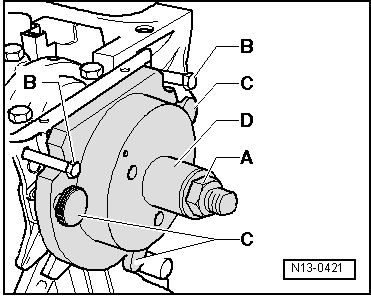

| Thread flange fastening bolts, alternating among them in cross. Tightening pair: 10 Nm |

|

|

|