Polo Mk4

| Clutch - repair |

| Special tools and workshop equipment required |

| t | Lock -3067- |

| t | Torque wrench - 5 to 50Nm (enc. 1/2") -VAG 1331- |

| t | Guide Pin -T 10086- |

| t | Guide Pin or VW 3190A -3190A- |

Note

Note

|

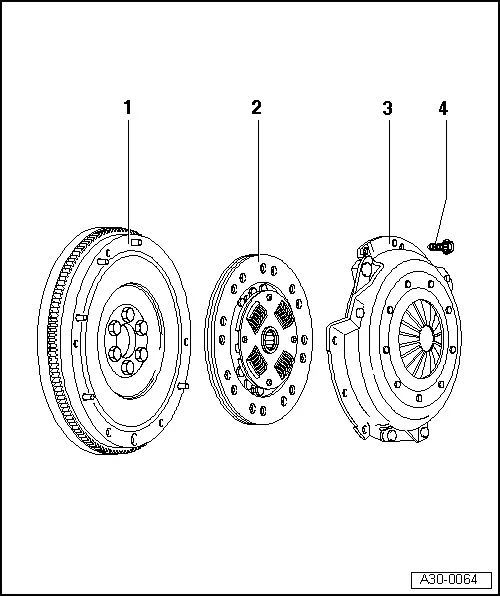

| 1 - | Engine flywheel |

| q | Pay attention on the perfect fitting of the guide pins |

| q | The contact surface of the clutch disc shall be free of oil and grease, and should not have grooves |

| q | Remove and install → Motor; Rep. Gr.13 |

| 2 - | Clutch disc |

| q | Installation position: the spring case shall be facing the clutch plate |

| q | centralization for vehicles with gasoline engine → Fig. |

| q | centralization for vehicles with gasoline engine → Fig. |

| q | Apply a slight coat of grease on the splines |

Note

Note| t | Clean the splines on the primary shaft and the clutch disc hub used. |

| t | Eliminate corrosion and apply a very fine coat of grease on the primary shaft splines. Move the clutch disc on the primary shaft to one side and other until the hub slides smoothly on the shaft. Eliminate the excess grease. Refer to → Chemical Materials Manual |

| 3 - | Clutch plate |

| q | Remove and install on vehicles with gasoline engine → Fig. |

| q | Remove and install on vehicles with gasoline engine → Fig. |

| q | Check membrane spring height → Fig. |

Note

Note| The clutch plates are greased and protected against corrosion. Clean the contact surface only; otherwise, the clutch lifetime will be significantly reduced. |

| 4 - | Screw |

| q | 20 Nm |

| q | Loosen and tighten in a cross and phased pattern |

Note

Note

|

|

|

|

|

|