Polo Mk4

| Transmission and clutch cases - repair |

| Special tools and workshop equipment required |

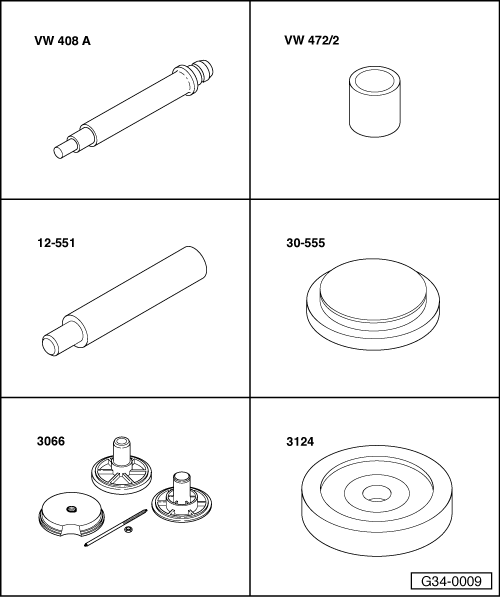

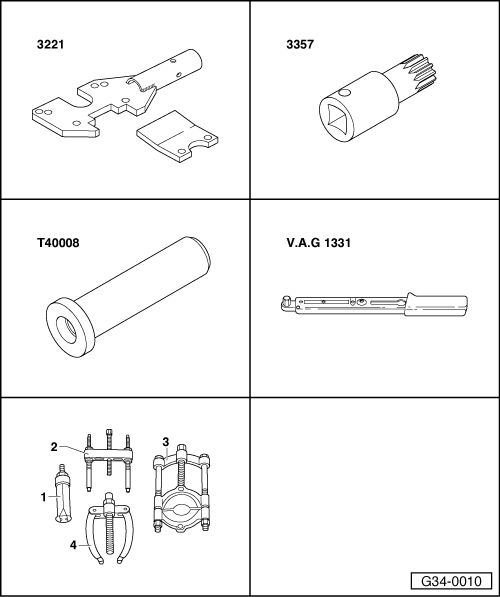

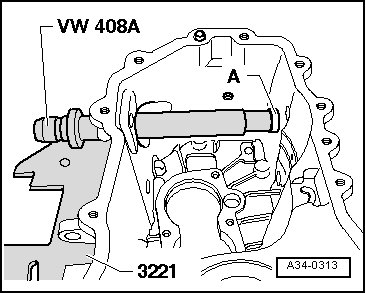

| t | Pressure pin -VW 408A- |

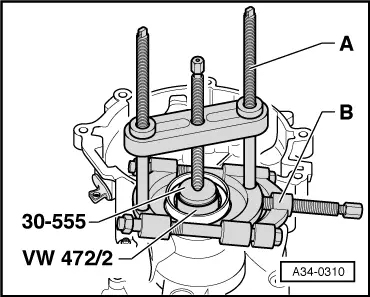

| t | Sleeve -VW 472/2- |

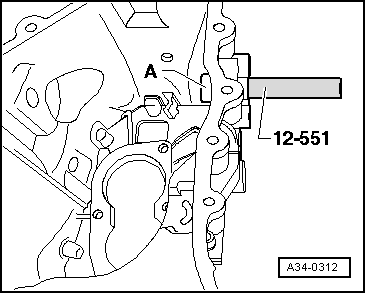

| t | Centring pin -12-551- |

| t | Pressure disc -30-555- |

| t | Assembly device -3066- |

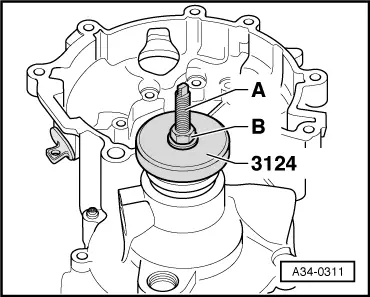

| t | Pressure plate -3124- |

| t | Support -3221- |

| t | Multi-teeth socket SW 27 -3357- |

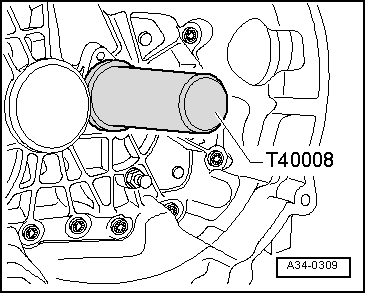

| t | Pressure tube -T 40008- |

| t | Torque wrench - 5 to 50Nm (enc. 1/2") -VAG 1331- |

| t | -2-Extractor 65 - 160 mm -KUKKO 18/1 - |

| t | -3-Spacer 12 - 75 mm -KUKKO 17/1 - |

| 1 - | Clutch case |

| q | Manufactured in aluminum or magnesium |

| q | Correspondence → Electronic Parts Catalogue |

| q | In case of replacement, always adjust differential → Chapter |

| 2 - | Sealing ring for primary shaft |

| q | Remove by leveraging with screwdriver. |

| q | Installation → Fig. |

| 3 - | Spherical pin |

| q | 20 Nm |

| q | Lubricate with grease, refer to → Chemical Materials Manual |

| 4 - | Sealing ring for the right propelling flange |

| q | Replace with the transmission installed → Chapter |

| 5 - | Bushing |

| q | For the sealing ring |

| q | Removal → Fig.. |

| q | Installation → Fig. |

| 6 - | Oil filling plug |

| q | 25 Nm |

| q | Use Multi-teeth socket SW 27 -3357- to remove and install |

| 7 - | O-ring |

| q | Always replace |

| 8 - | Speed sensor -G22- |

| 9 - | Screw |

| q | 5 Nm + 90° |

| q | Always replace |

| 10 - | Adjustment shim S2 |

| q | For the differential |

| q | Determine thickness → ChapterReference |

| 11 - | Outside ring on the tapered roller bearing |

| q | For the differential |

| q | Remove → Fig. |

| q | Install → Fig. |

| q | In case of replacement, always adjust differential → Chapter |

| 12 - | Screw |

| q | 5 Nm + 90° |

| q | always replace |

| 13 - | Outside ring on the tapered roller bearing |

| q | For the differential |

| q | Removal → Fig.. |

| q | Installation → Fig. |

| q | In case of replacement, always adjust differential → Chapter |

| 14 - | Adjustment shim S1 |

| q | For the differential |

| q | Always with 1-mm thickness |

| 15 - | Adjustment pin |

| q | 2 units |

| 16 - | Transmission case |

| q | Manufactured in aluminum or magnesium |

| q | Correspondence → Electronic Parts Catalogue |

| q | Repair → Chapter |

| q | In case of replacement, always adjust differential → Chapter |

| q | Apply Sealing putty -AMV 188 200 03- evenly on the sealing surface of the transmission case |

| 17 - | Oil draining plug |

| q | 25 Nm |

| 18 - | Sealing ring for the left propelling flange |

| q | Replace with the transmission installed → Chapter |

| 19 - | Bushing |

| q | For the selector lever shaft |

| q | Removal → Fig. |

| q | Installation → Fig. |

| 20 - | Magnet |

| q | Fastened on the case surface |

| 21 - | Reservoir lid |

| q | Apply Sealing putty -AMV 188 200 03- evenly on the sealing surface before installing |

| 22 - | Circlip |

| q | Install on the tapered roller bearing groove → Item |

| 23 - | Circlip |

| q | Install on the tapered roller bearing groove → Item |

| 24 - | Tapered roller bearing |

| q | For primary shaft |

| q | Removal → Fig.. |

| q | Installation → Fig. |

| 25 - | Tapered roller bearing |

| q | For pinion shaft |

| q | Removal → Fig. |

| q | Installation → Fig. |

|

|

|

|

|

|

|

|

Note

Note