Polo Mk4

| Pinion shaft - disassemble and assemble |

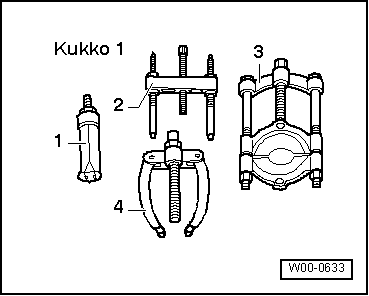

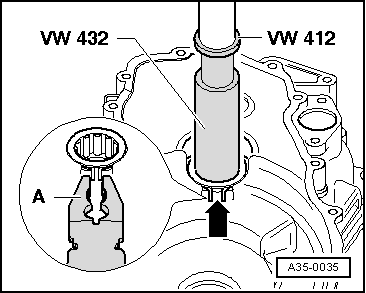

| Special tools and workshop equipment required |

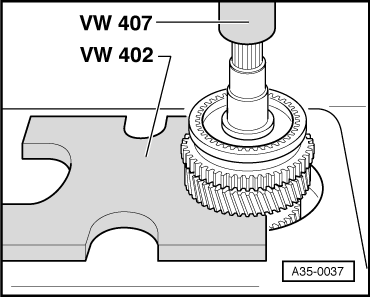

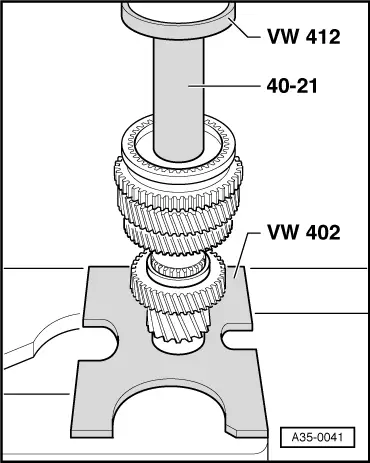

| t | Plate -VW 402- |

| t | Pressure pin -VW 407- |

| t | Pressure disc -VW 412- |

| t | Pressure tube -VW 415A- |

| t | Pressure base -VW 432- |

| t | Supporting tube -40-21- |

|

Note

Note

|

|

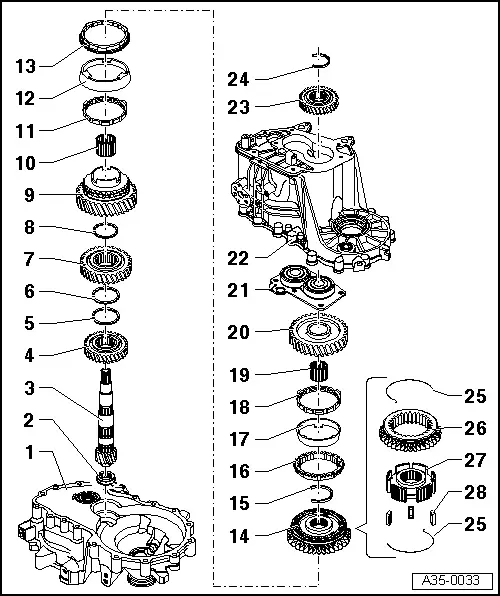

| 1 - | Clutch case |

| 2 - | Tapered roller bearing |

| q | With circlip |

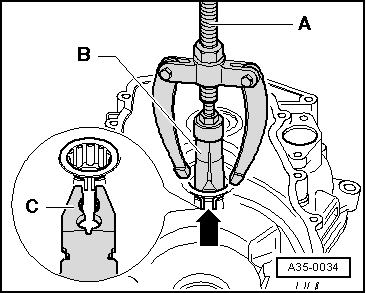

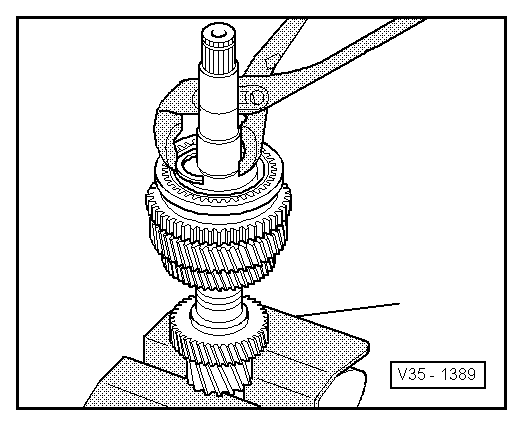

| q | Removal → Fig. |

| q | Installation → Fig. |

| q | Installation position: the circlip shall face the pinion shaft |

| 3 - | Pinion shaft |

| q | If replacement is required, the differential master gear must also be replaced → Item. |

| q | If there is an inside ring as tapered roller bearing housing, this should not be removed from the pinion shaft. |

| q | If scratches or damages are detected on the bearing housing or inside ring, replace the pinion shaft and the tapered roller bearing as a set. |

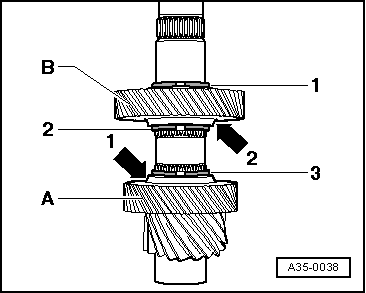

| 4 - | 4th gear wheel |

| q | Installation position: the hub shall face the 3rd gear → Fig. |

| 5 - | Circlip |

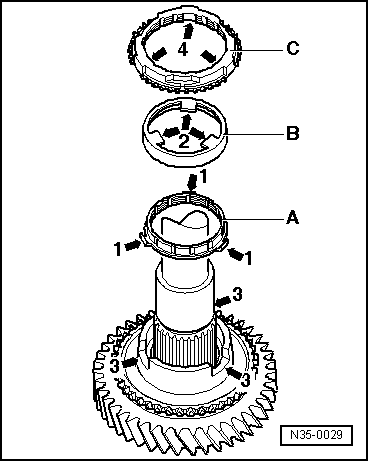

| 6 - | Circlip |

| 7 - | 3rd gear wheel |

| q | Installation position: the hub shall face the 3rd gear → Fig. |

| 8 - | Circlip |

| 9 - | 2nd gear wheel |

| 10 - | Needle bearing |

| q | For 2nd gear |

| 11 - | Inside ring for 3rd gear |

| q | Wear check → Fig. |

| q | Installation position → Fig. |

| 12 - | Outside ring for 2nd gear |

| q | Install on inside ring → Item |

| q | Change in case of scratches or wear signs |

| q | Installation position → Fig. |

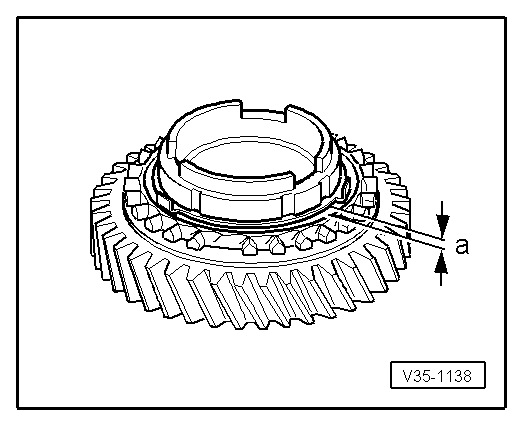

| 13 - | Synchroniser ring for 2nd gear |

| q | Wear check → Fig. |

| q | Installation position → Fig. |

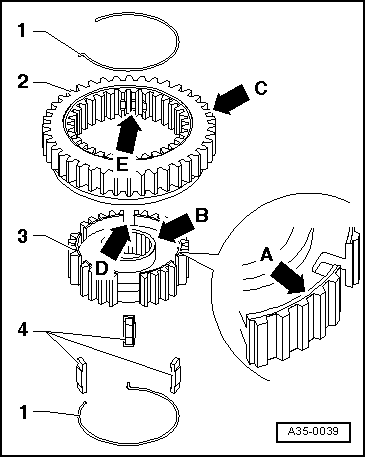

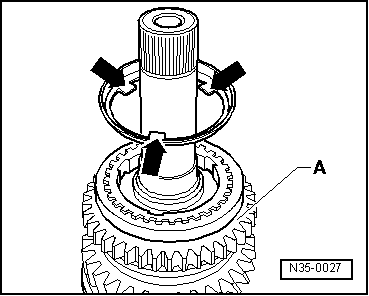

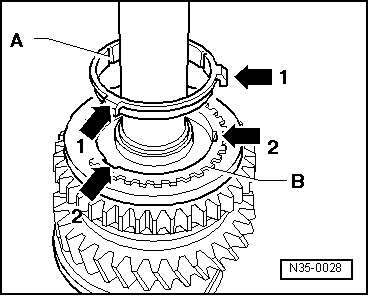

| 14 - | Engaging sleeve with 1st and 2nd gear synchroniser |

| q | Remove with 2nd gear wheel after removing the circlip → Fig. |

| q | Disassemble and assemble the engaging sleeve/synchroniser ring → Fig. |

| q | Installation → Fig. |

| 15 - | Circlip |

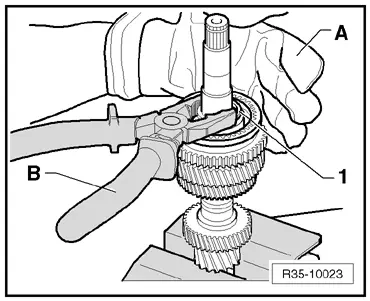

| q | Removal → Fig.. |

| q | Installation → Fig. |

| 16 - | Synchroniser ring for 1st gear |

| q | Wear check → Fig. |

| q | Install in order that the notches fit in the engaging sleeve limiters → Item |

| 17 - | Outside ring for 1st gear |

| q | Install on synchroniser ring → Item |

| q | Installation position → Fig. |

| q | Change in case of scratches or wear signs |

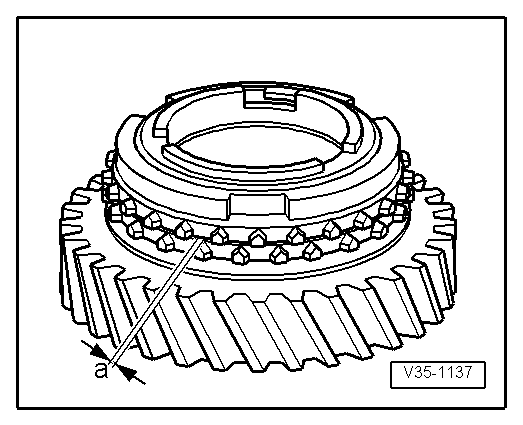

| 18 - | Inside ring for 1st gear |

| q | Wear check → Fig. |

| q | Check the flanges for wear signs |

| q | Installation position → Fig. |

| 19 - | Needle bearing |

| q | For 1st gear |

| 20 - | 1st gear wheel |

| q | Installation position → Fig. |

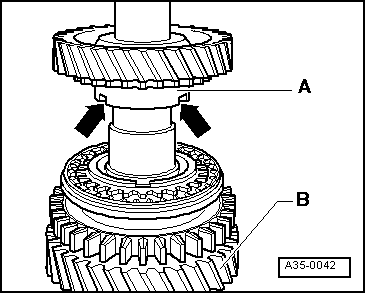

| 21 - | Bearing support with ball bearing |

| q | Change bearing support with ball bearing |

| q | Clean the threaded holes of the bearing support (e.g. Tap M6) |

| q | Removal → Fig.. |

| q | Installation → Fig. |

| 22 - | Transmission case |

| 23 - | 5th gear wheel |

| q | Installation position: the hub shall face the transmission case side → Fig. |

| 24 - | Circlip |

| q | Always replace |

| q | Determine thickness → Anchor |

| 25 - | Spring |

| q | Installation position → Fig. |

| 26 - | Engaging sleeve |

| 27 - | Synchroniser |

| 28 - | Retainers |

| q | 3 units |

|

|

|

|

|

|

|

|

|

|

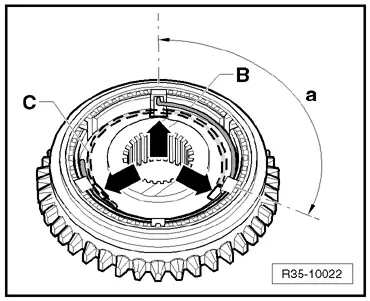

| Distance -a- | New part | Wear limit |

| 1st and 2nd gears | 0,75 ... 1.25 mm | 0.3 mm |

|

|

| Distance -a- | New part | Wear limit |

| 1st and 2nd gear | 1,2 ... 1.8 mm | 0.5 mm |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING