| Installation is performed in reverse sequence to the removal,

considering the following: |

WARNING | Replace self-locking nuts and screws subject to angular torque |

|

| t

| Use new sealants for the hoses/ducts |

| t

| Lubricate the steering box joint with lubricant such as soap,

for example, before installing the steering box |

| t

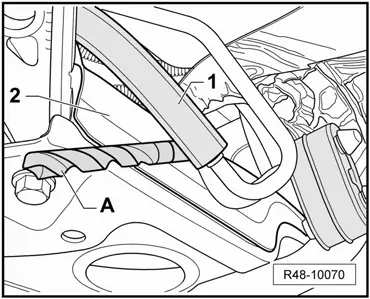

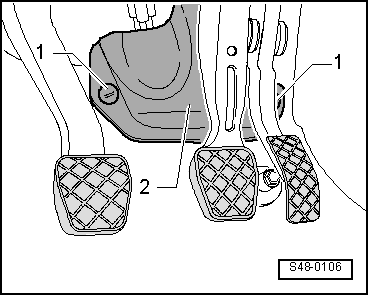

| After fitting the steering box in the universal joint of the

column, make sure that the joint is against the assembly plate, without

twisting, and that it seals the opening for the pedal area correctly.

There may be noises and even water infiltration |

| t

| Make sure that the sealing surfaces are clean |

| t

| When replacing the electrohydraulic steering box, also replace

the steering yoke bellows |

| Before installing the auxiliary frame (sub-frame)

screws, position the electrohydraulic steering box on the auxiliary

frame and install the screws for the electrohydraulic steering box. |

| –

| Install the auxiliary frame (sub-frame) → Chapter. |

| –

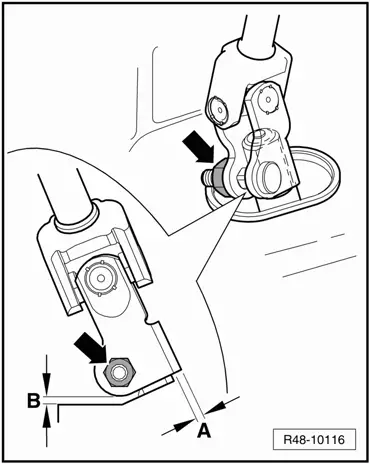

| Install the steering box to the auxiliary frame. Tightening

torque, see → Anchor. |

| –

| Install the steering linkage bar to the steering arm. Tightening

torque, see → Anchor. |

| –

| Install the Electrohydraulic steering box -G250- → Chapter. |

| –

| Install the return hose and tighten the connecting screw. |

|

|

|

Note

Note Note

Note

Note

Note

WARNING

WARNING