Polo Mk5

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

| Specified torques |

| Component | Specified torque | ||||||

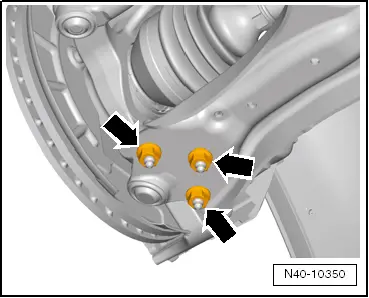

Swivel joint to suspension link

| 100 Nm | ||||||

Drive shaft to flange shaft on gearbox “M8 multi-point socket”

| 40 Nm

| ||||||

Drive shaft to flange shaft on gearbox “M10 multi-point socket”

| 70 Nm

| ||||||

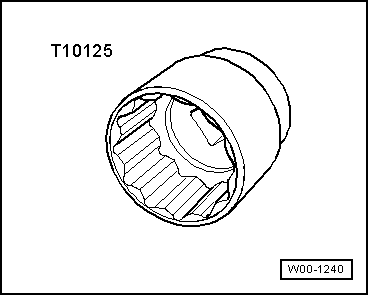

12-point nut on drive shaft

| 50 Nm + 45° |