| t

| If a new air conditioner compressor is installed, a „compressor run-in“ must be carried out → Anchor. |

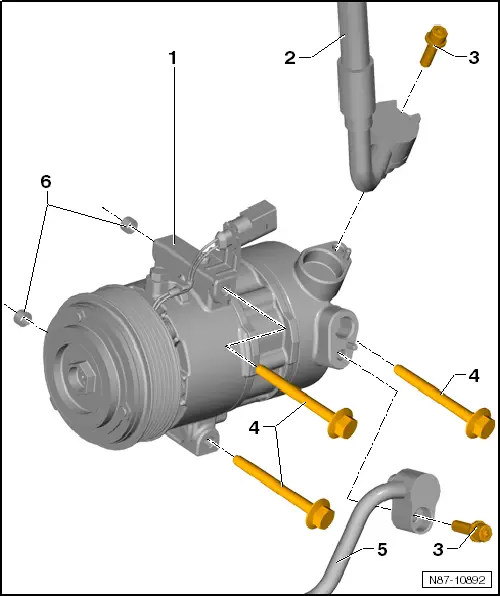

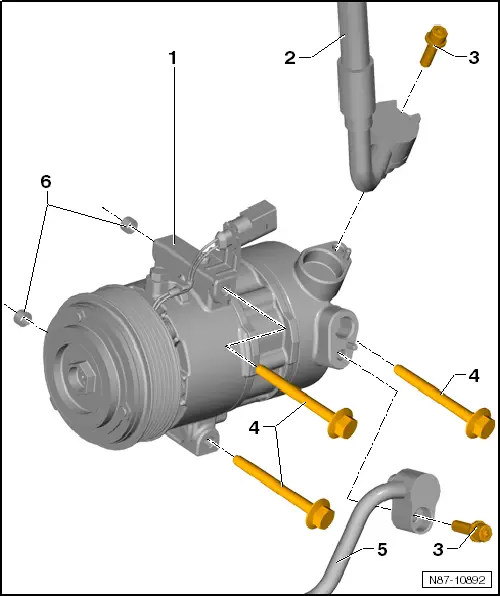

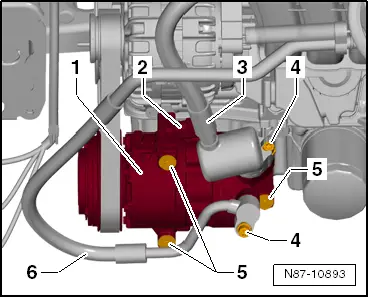

| Notes on installing air conditioner compressor |

| –

| Only start engine after refrigerant circuit has been assembled. |

| –

| After installing a new air conditioner compressor or filling with fresh refrigeration oil (e.g. after purging refrigerant circuit), turn air conditioner compressor poly V-belt pulley 10 revolutions by hand before starting engine. This will prevent damage to the air conditioner compressor. |

| –

| If possible, only start engine when refrigerant circuit is full. |

Note | t

| The air conditioner compressor is driven by the air conditioning system magnetic clutch -N25-. |

| t

| The air conditioning system magnetic clutch -N25- only starts if it receives a signal from the high-pressure sender -G65- to avoid damage to the compressor when refrigerant circuit is empty. |

Note | Note the following when starting engine for first time after filling refrigerant circuit: |

| –

| Start engine with air conditioner compressor switched off (control lamp in AC button is off) and wait until idling speed is stable. |

| –

| Fresh air blower -V2- at least set to 3. |

| –

| Set temperature to „Cold“ on control and display unit for air conditioning system. |

| –

| Switch on air conditioner compressor (control lamp in AC button lights up) and let it run for at least 5 minutes with engine at idling speed. |

| Air conditioner compressor run-in |

Note | If a new air conditioner compressor is installed, a „compressor run-in“ must be carried out → Anchor. |

| The following conditions must first be met: |

| l

| Compressor filled with refrigerant filled at pressure end |

| l

| Air conditioning system off (warning lamp in AC button off) |

| –

| Wait approx. 5 seconds until idling has stabilised. |

| –

| Switch on air conditioning system (warning lamp in AC button on). |

| –

| Allow engine to idle for 2 minutes. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note Note

Note