| –

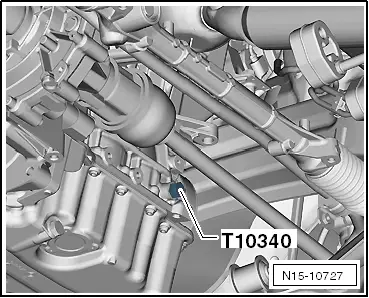

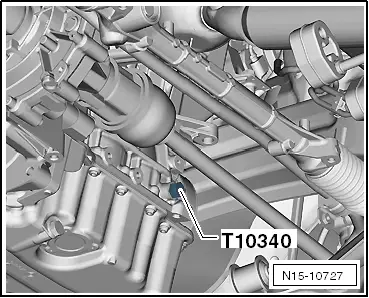

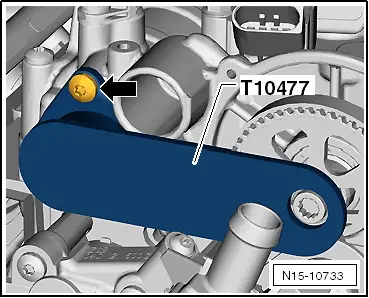

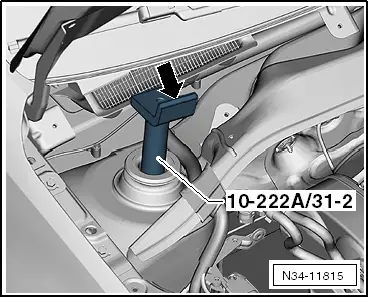

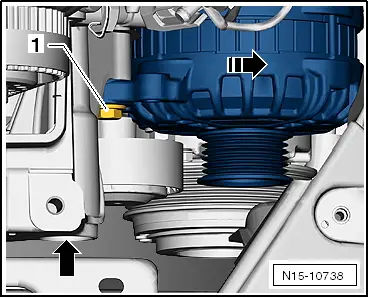

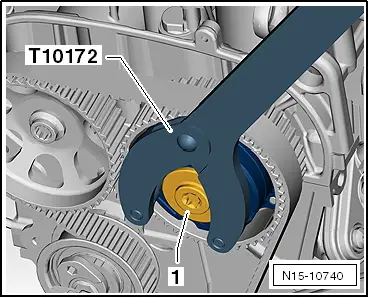

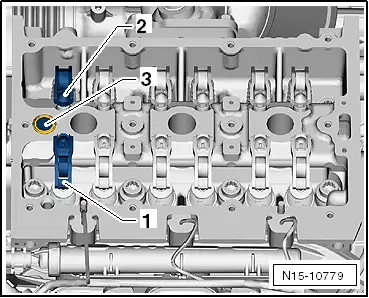

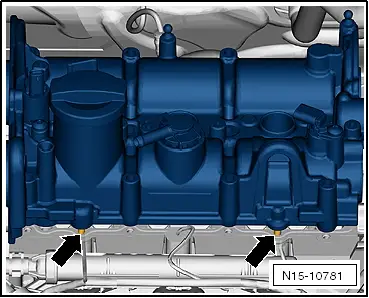

| Screw locking pin -T10340- into crankcase from above as far as it will go. |

Caution | If locking pin -T10340- cannot be screwed in as far as stop, this indicates that crankshaft is not in the correct position! |

| In this case, proceed as follows. |

|

| –

| Turn crankshaft 90° in direction of rotation of engine. |

| –

| Screw locking pin -T10340- into crankcase as far as it will go. |

| –

| Tighten locking pin -T10340- to 30 Nm. |

| –

| Turn crankshaft in direction of rotation of engine as far as the stop. |

| Locking pin -T10340- locks crankshaft in direction of engine rotation. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution