| –

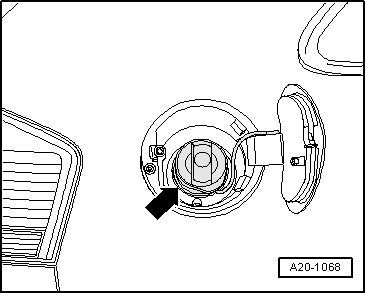

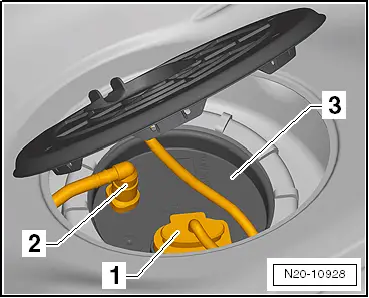

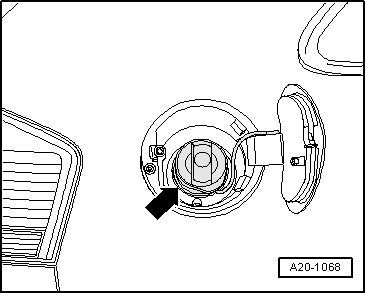

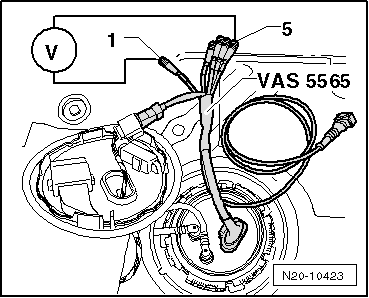

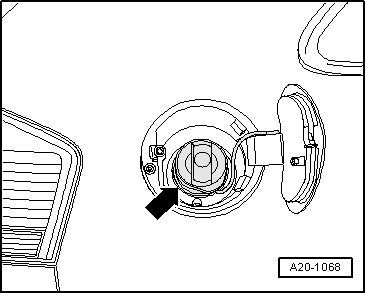

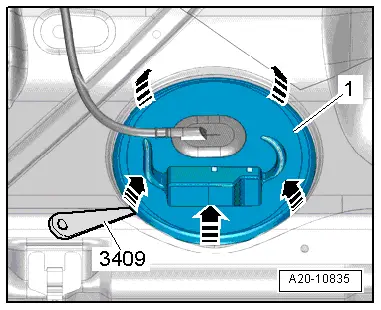

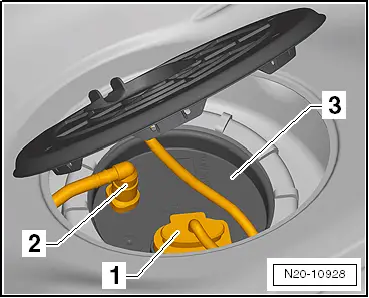

| Remove cap -arrow- from fuel filler neck. |

| –

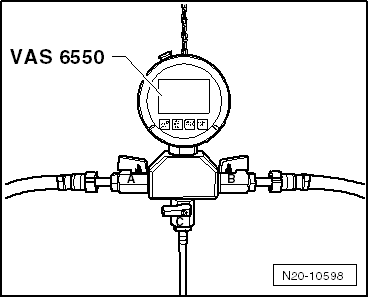

| Repeat delivery rate check. |

| –

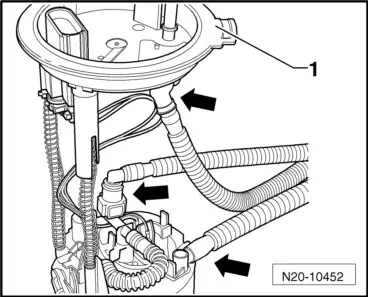

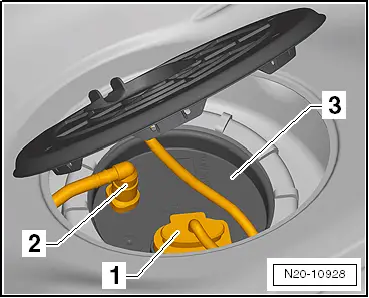

| If fuel delivery rate is now reached, check fuel tank breather → Chapter. |

| If the specifications are still not attained: |

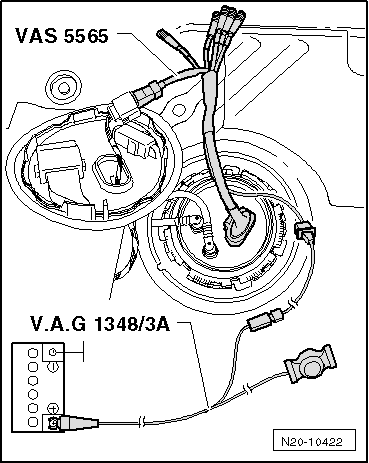

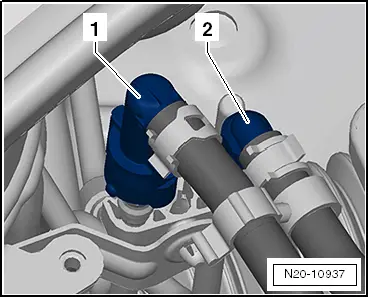

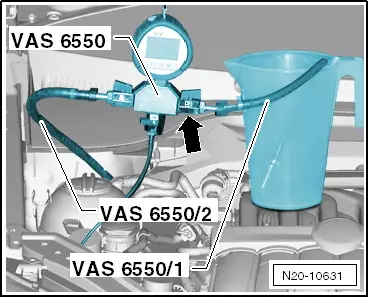

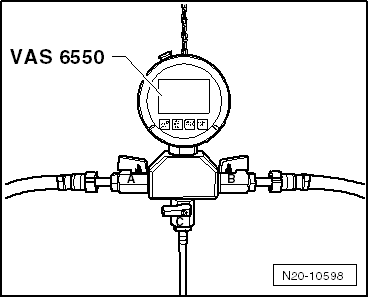

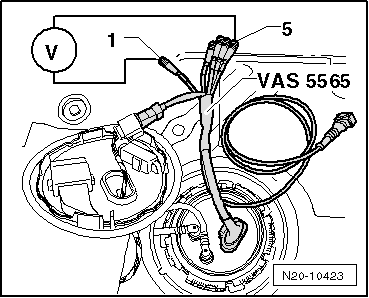

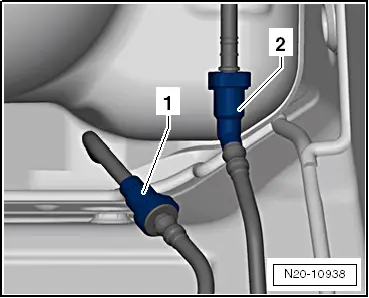

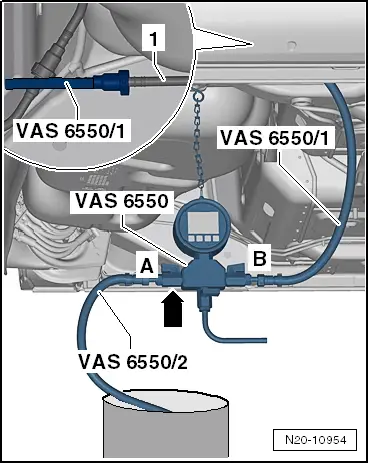

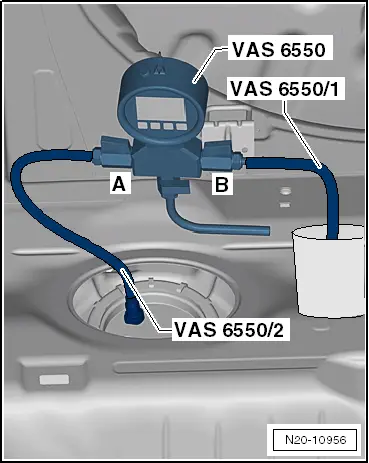

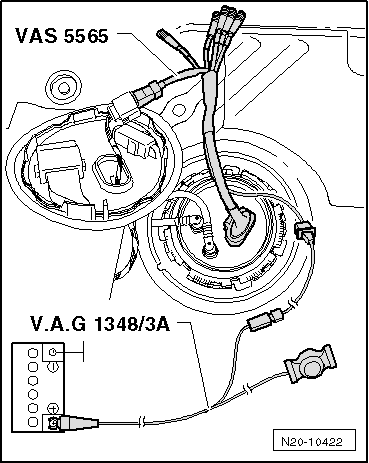

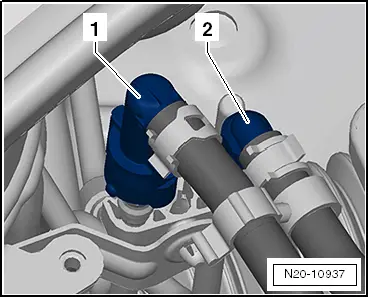

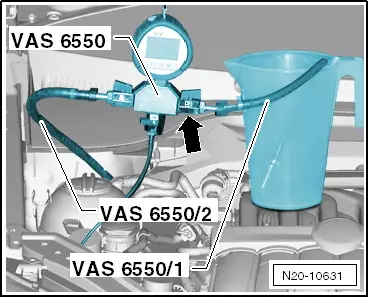

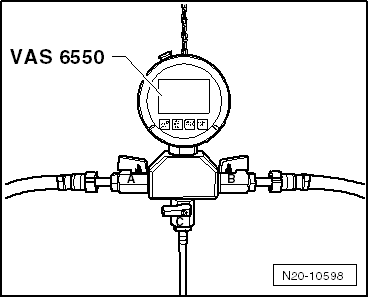

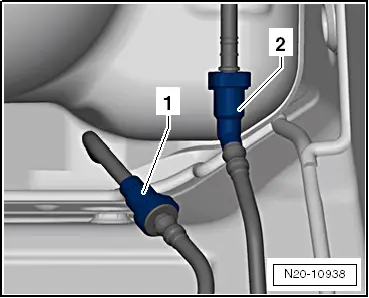

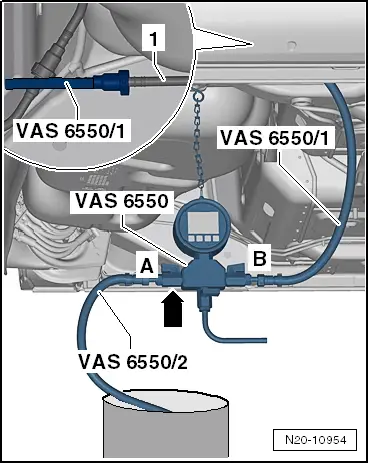

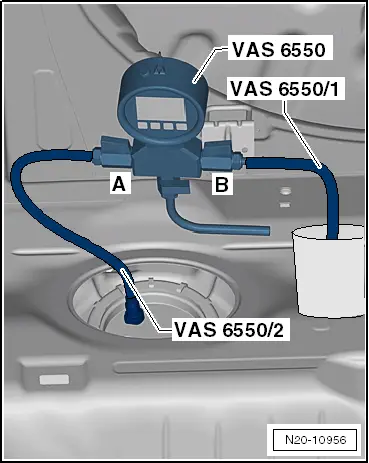

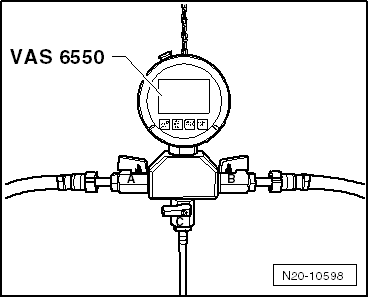

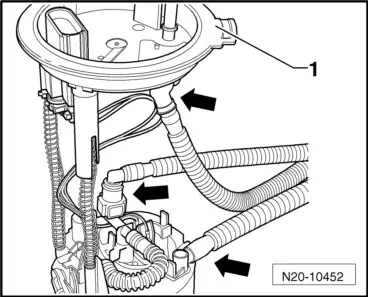

| Proceed as follows to check fuel delivery rate at separating point on underbody: |

WARNING | Fuel supply line is pressurised. Wear eye protection and protective clothing to avoid eye injuries and skin contact. Before loosening hose connections, wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note