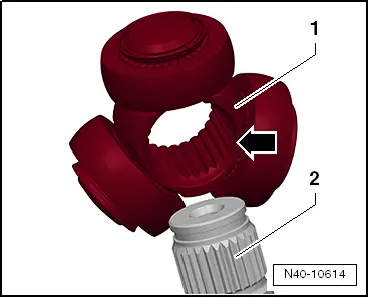

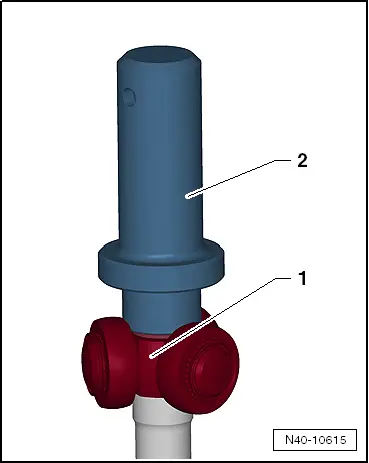

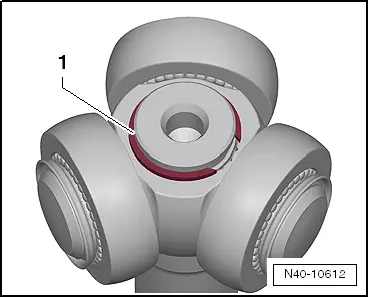

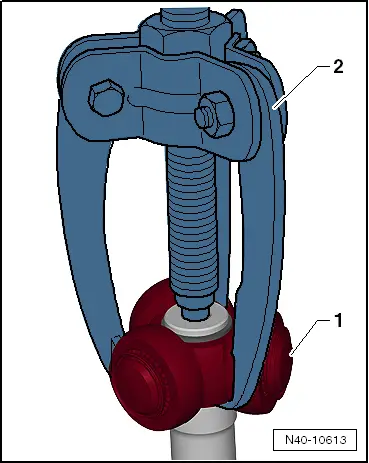

| Tightening new clamp on constant velocity joint |

| –

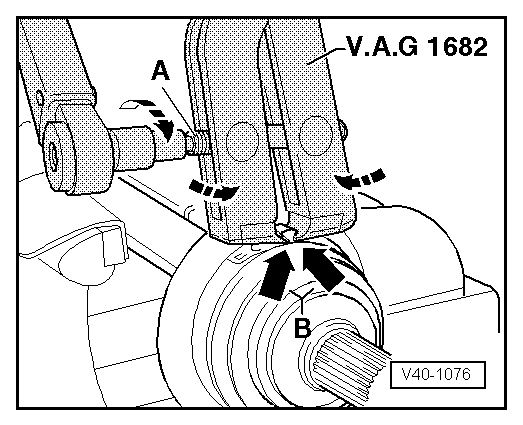

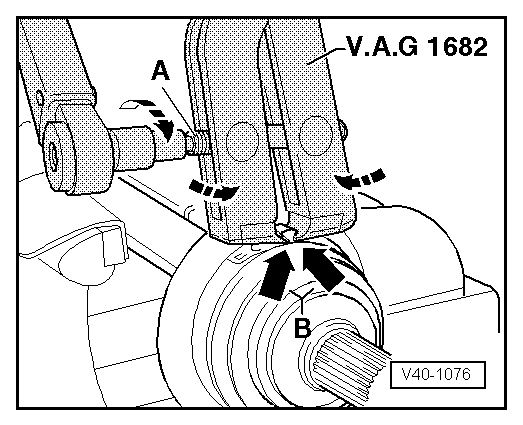

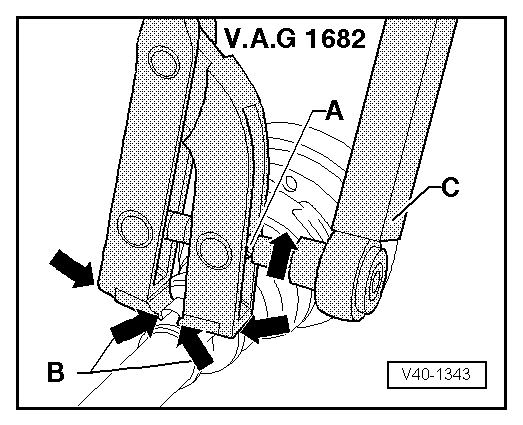

| Position clamp tensioner -V.A.G 1682- as shown in diagram. Ensure jaws of tensioner lie in corners -arrows B- of clamp. |

| –

| Tighten clamp by turning spindle with a torque wrench (do not cant pliers). |

Note | t

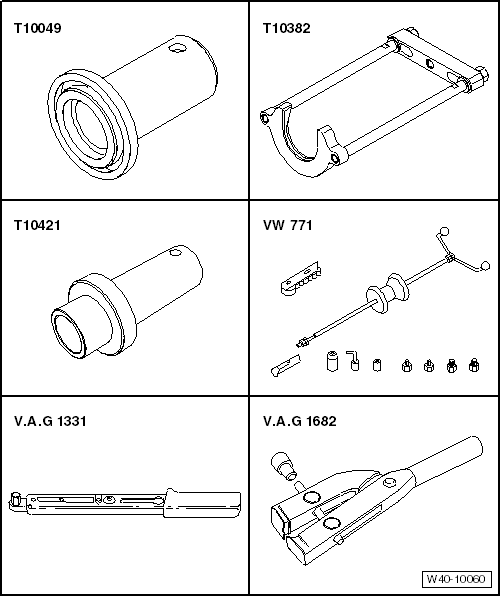

| Due to the hard material of the protective boot (compared to rubber) and the necessity of using a stainless steel clamp, it is only possible to tension the clamp with clamp tensioner -V.A.G 1682-. |

| t

| Specified torque: 25 Nm. |

| t

| Use torque wrench -C - with setting range of 5 ... 50 Nm (e.g. torque -V.A.G 1331-). |

| t

| Make sure thread of spindle -A- on pliers moves freely. Lubricate with MoS2 grease if necessary. |

| t

| If the thread is tight (e.g. due to dirt), the required clamping force for the clamp will not be attained although the specified tightening torque is applied. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note