| General notes concerning repairs to vehicle electrical system |

Caution | When batteries are disconnected and reconnected, the procedure described in the workshop manual must be strictly observed. |

|

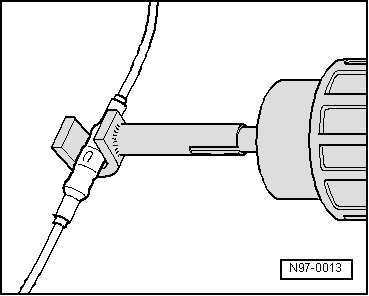

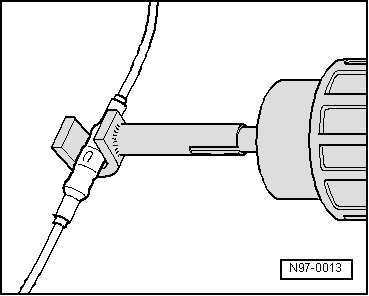

WARNING | Some tools are equipped with a tool safety device. This must be pushed over the tip of the tool after use in order to protect the tip and prevent personal injury. |

|

| t

| Observe the latest notes in the respective workshop manual when carrying out repairs. |

| t

| Observe country-specific regulations. |

| t

| Always disconnect the battery earth strap before working on the electrical system. Disconnecting the battery earth strap (open circuit) provides a safe working environment for repairs to the electrical system. The battery positive wire need only be disconnected for removal of the battery. |

| t

| Before starting a repair, it is important to identify and rectify the cause of damage (e.g. sharp edges on body panels, defective electrical components, corrosion, etc.). |

| t

| For additional information, e.g. removal and installation of individual components, please refer to the relevant workshop manual. |

|

|

|