A1

|

| Special tools and workshop equipment required |

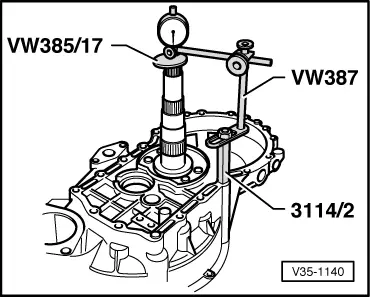

| t | Universal dial gauge bracket -VW 387- |

| t | End measuring plate -VW 385/17- |

| t | Thrust pad -VW 512- |

| t | Straightening tool -3114/2- |

| t | Press tool -VW 407- |

| t | Torque wrench -V.A.G 1331- |

| t | Dial gauge |

|

|

Note

Note

|

|

|

|

| Bearing clearance = shim (0.65 mm) + measured value (0.18 mm) | Thickness of shim according to table |

| 0.830 mm | 0.950 mm |

|

| Bearing clearance = shim (0.65 mm) + measured value | Thickness of shim (mm) |

| 0.650 0.660 … 0.689 | 0.750 0.800 |

| 0.690 … 0.739 0.740 … 0.789 0.790 … 0.839 | 0.850 0.900 0.950 |

| 0.840 … 0.889 0.890 … 0.939 0.940 … 0.989 | 1.000 1.050 1.100 |

| 0.990 … 1.039 1.040 … 1.089 1.090 … 1.139 | 1.150 1.200 1.250 |

| 1.140 … 1.189 1.190 … 1.239 1.240 … 1.289 | 1.300 1.350 1.400 |

| 1.290 … 1.339 1.340 … 1.389 1.390 … 1.429 | 1.450 1.500 1.550 |

Note

Note

|