Caution | Make sure lubrication system is not clogged by excess sealant. |

| The bead of sealant must not be thicker than specified. |

|

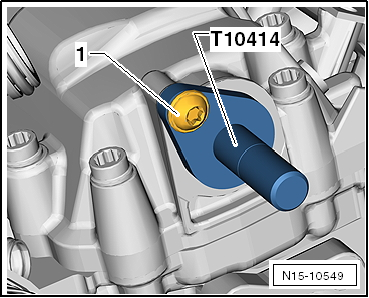

| –

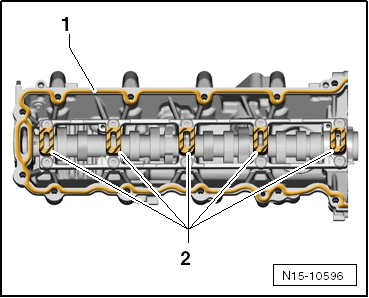

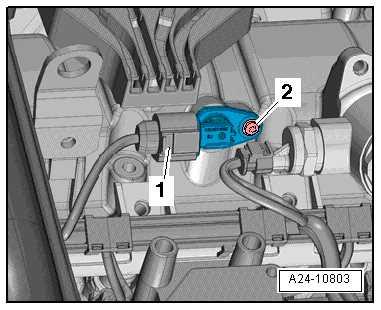

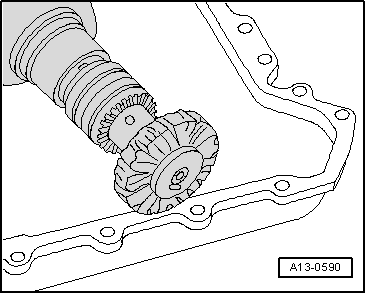

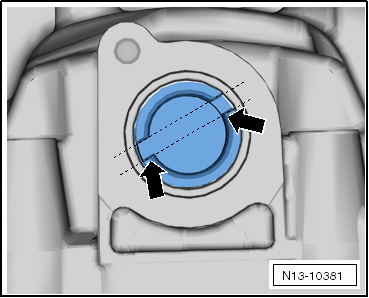

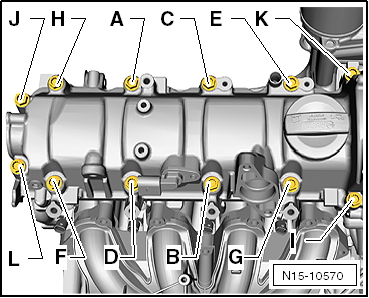

| Apply bead of sealant -1- onto clean sealing surface of camshaft housing, as shown in illustration. |

| l

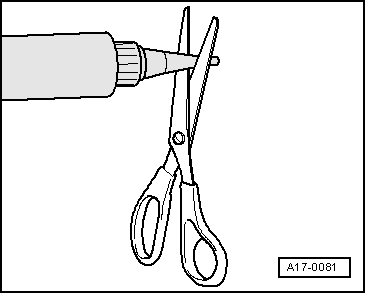

| The bead of sealant must be 2.0 … 3.0 mm thick. |

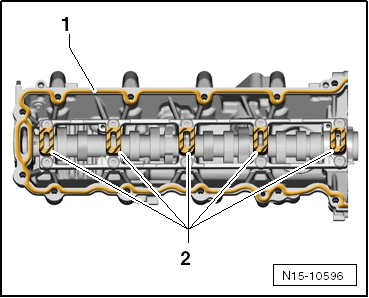

| –

| Apply a thin and even layer of sealant to clean sealing surfaces of camshaft housing (hatched areas -2- in illustration). |

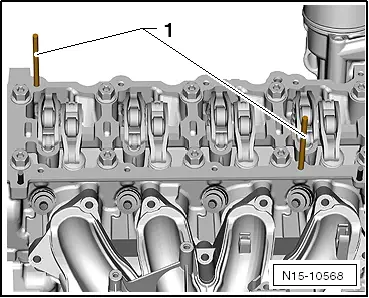

| –

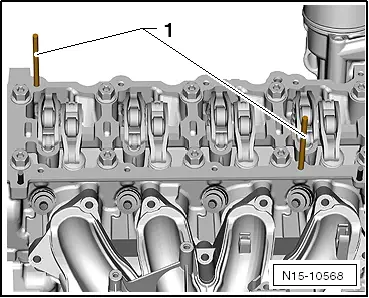

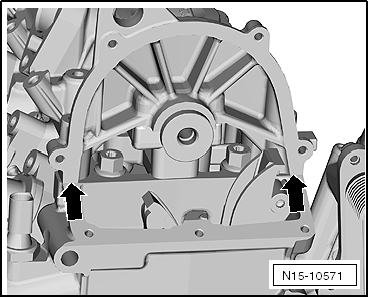

| Make sure that all roller rocker fingers make contact with the valve ends correctly and are clipped into their respective support elements. |

Note | The camshaft housing must be installed within 5 minutes after applying the sealant. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING