| –

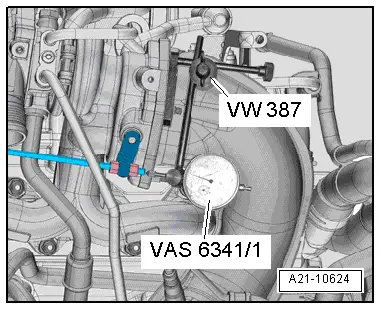

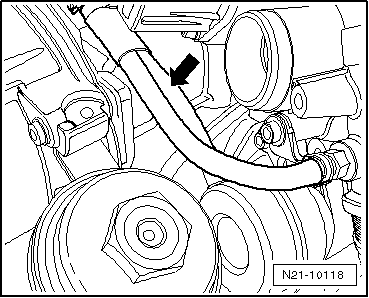

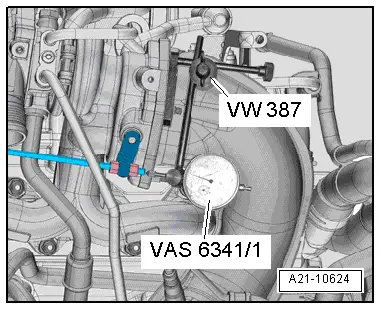

| Attach dial gauge -VAS 6341/1- to universal dial gauge bracket -VW 387-. |

| –

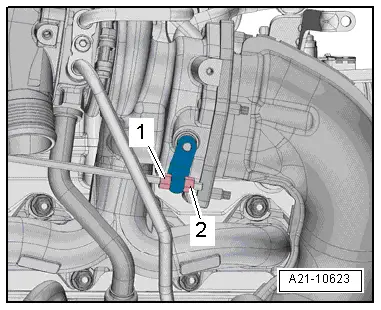

| Secure universal dial gauge bracket -VW 387- to turbocharger as shown in illustration. |

| l

| The dial gauge linkage must be in line with the linkage of the vacuum unit. |

| –

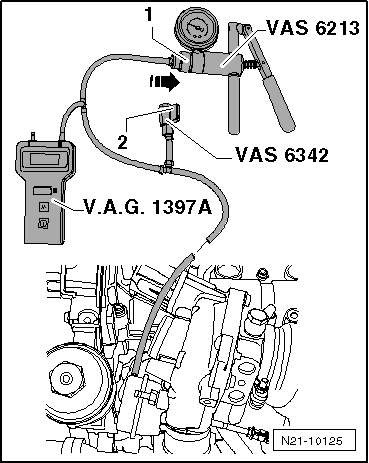

| With pressure at 0 bar, set dial gauge -VAS 6341/1- to 1 mm preload. |

| –

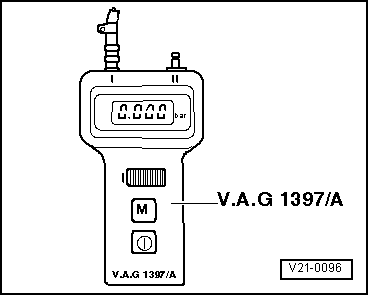

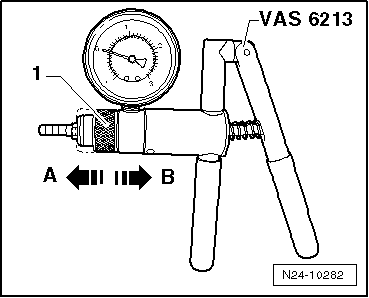

| Operate hand vacuum pump -VAS 6213- several times until the pressure displayed on turbocharger tester -V.A.G 1397A- is approx. 800 mbar. |

| l

| Specification on dial gauge -VAS 6341/1-: 1 mm travel |

| –

| Vent system via pressure control valve -VAS 6342- so that pressure reading drops to 0 mbar. |

| Checking adjustment of vacuum unit |

| –

| Set scale of dial gauge -VAS 6341/1- to „0“. |

Note | The following measurements must be performed in the specified sequence. Do not allow the pressure to drop to 0 between measurements. |

| –

| Operate hand vacuum pump -VAS 6213- several times until a pressure of 500 ± 5 mbar is displayed on turbocharger tester -V.A.G 1397A-. |

| –

| Read off and note travel indicated on dial gauge -VAS 6341/1-. |

| –

| Operate hand vacuum pump -VAS 6213- several times until a pressure of 800 ± 5 mbar is displayed on turbocharger tester -V.A.G 1397A-. |

| –

| Vent system via pressure control valve -VAS 6342- so that pressure reading drops to 500 ± 5 mbar. |

| –

| Read off and note travel indicated on dial gauge -VAS 6341/1-. |

| –

| Determine average value: add values „1“ and „2“ together and divide by 2. |

| l

| Specification: 5.50 ± 0.25 mm. |

Note |

|

|

Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution