A2

| Removing gearbox |

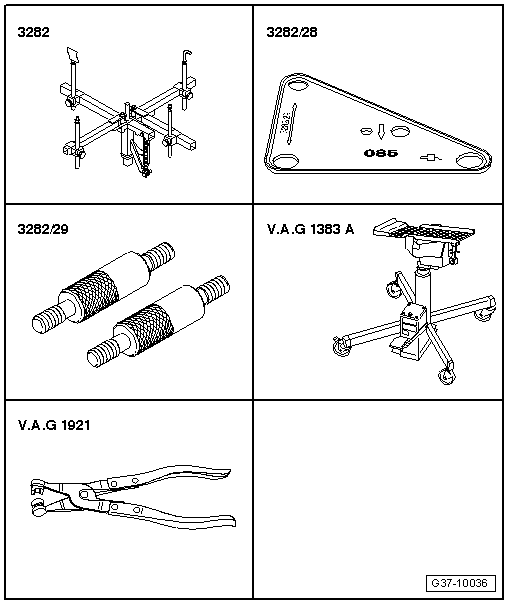

| Special tools and workshop equipment required |

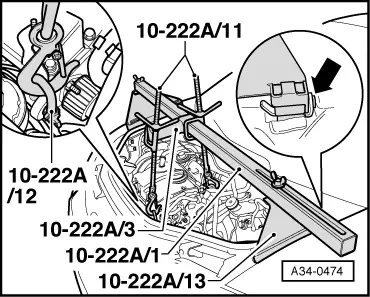

| t | Support bracket -10 - 222 A- |

| t | Adapter -10 - 222 A /3- |

| t | Shackle -10 - 222 A /12- |

| t | Adapter -10 - 222 A /13- |

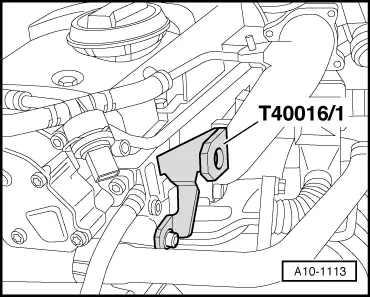

| t | Transportation shackle -T40016- |

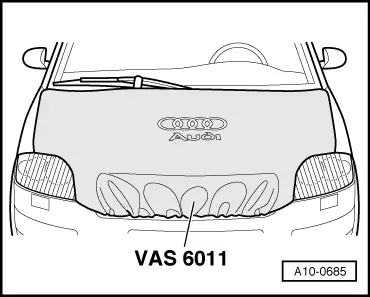

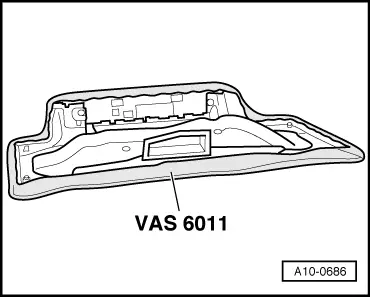

| t | Protective cover for bonnet Audi A2 -VAS 6011- |

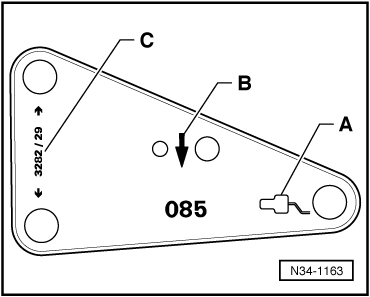

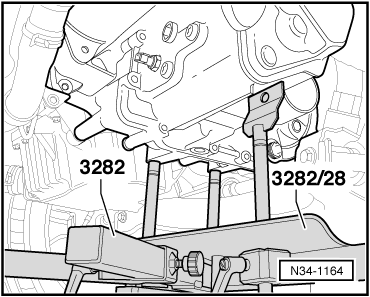

| t | Gearbox support -3282- |

| t | Adjustment plate -3282/28- |

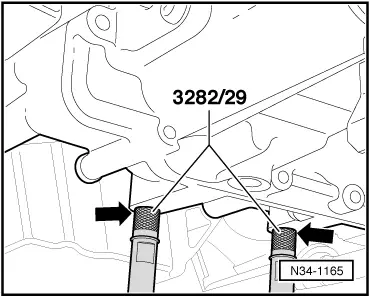

| t | Pin -3282/29- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Hose clip pliers -V.A.G 1921- |

Note

Note

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution