A2

Note

Note

|

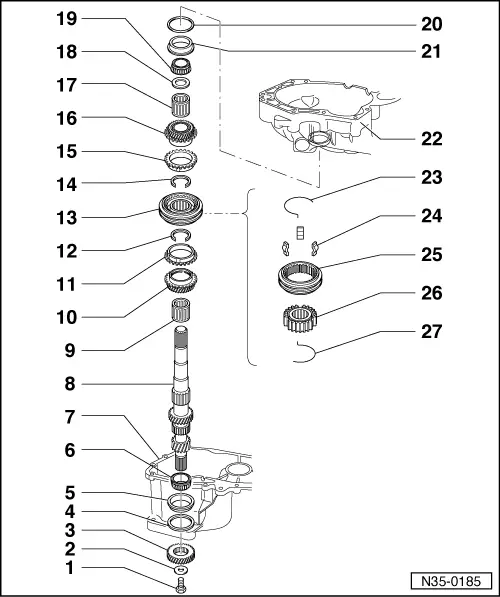

| 1 - | Bolt |

| q | Fitted piece on bolt head holds dished spring in position |

| q | 40 Nm |

| 2 - | Dished spring |

| 3 - | 5th gear wheel |

| q | Removing and installing → Item |

| 4 - | Washer |

| q | 1 mm thick |

| 5 - | Tapered roller bearing outer race |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| 6 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 7 - | Gearbox housing |

| 8 - | Input shaft |

| q | Adjusting → Chapter |

| 9 - | Needle bearing |

| q | Oil before installing |

| 10 - | 3rd speed selector gear |

| q | Pressed off → Fig. and pressed on → Fig. together with locking collar/synchro-hub for 3rd and 4th gear |

| 11 - | 3rd gear synchro-ring |

| q | Checking for wear → Fig. |

| 12 - | Circlip |

| q | Pressing out → Fig. |

| q | Fitting → Fig. |

| 13 - | Locking collar with synchronising hub for 3rd and 4th gear |

| q | Parts are paired |

| q | Pressing off → Fig. |

| q | Assembly → Fig. and → Fig. |

| q | Pressing on → Fig. |

| 14 - | Circlip |

| q | Pressing out → Fig. |

| q | Fitting → Fig. |

| 15 - | 4th gear synchro-ring |

| q | Checking for wear → Fig. |

| 16 - | 4th speed selector gear |

| 17 - | Needle bearing |

| q | Oil before installing |

| 18 - | Thrust washer |

| 19 - | Tapered roller bearing inner race |

| q | Can be removed without tools |

| 20 - | Shim |

| q | Determining thickness → Chapter „Adjusting input shaft“ |

| 21 - | Tapered roller bearing outer race |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 22 - | Clutch housing |

| 23 - | Spring |

| q | Installation position → Fig. |

| 24 - | Locking piece |

| q | 3x |

| 25 - | Locking collar |

| 26 - | Synchronising hub |

| 27 - | Spring |

| q | Installation position → Fig. |