A2

Note

Note

|

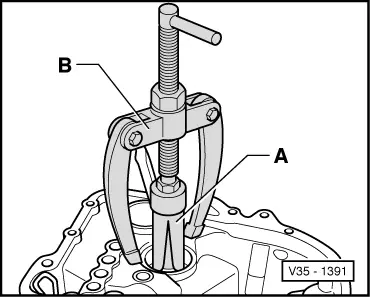

| Special tools and workshop equipment required |

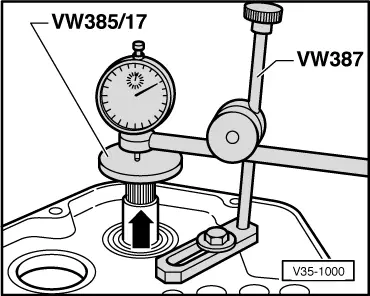

| t | Universal dial gauge bracket -VW 387- |

| t | Measuring device d = 50 mm -VW 385/17- from universal measuring device -VW 385- |

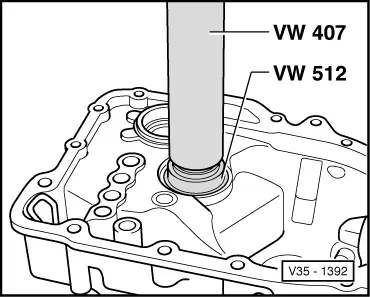

| t | Thrust pad -VW 512- |

| t | Press tool -VW 407- |

|

|

|

|

|

|

|

|

Note

Note

|

|

| Example: | |

| Inserted shim | 0.75 mm |

| Dial gauge reading (example) | + 0.30 mm |

| Preload (constant value) | + 0.20 mm |

| Thickness of shim | = 1.25 mm |

|

| Available shims - Thickness of shims in mm 1) | ||||

| 0.70 | 1.00 | 1.30 | ||

| 0.75 | 1.05 | 1.35 | ||

| 0.80 | 1.10 | 1.40 | ||

| 0.85 | 1.15 | |||

| 0.90 | 1.20 | |||

| 0.95 | 1.25 | |||

| ||||

|

|