A2

| Valve gear - exploded view of components |

| 1 - | 20 Nm + 90° (1/4 turn) further |

| q | Renew |

| q | Note correct sequence for loosening and tightening → Chapter „Removing and installing camshaft“ |

| 2 - | Rocker arm shaft |

| q | Note correct sequence for loosening and tightening → Chapter „Removing and installing camshaft“ |

| 3 - | Cylinder head bolt |

| q | Renew |

| q | Note correct sequence for loosening and tightening → Chapter „Removing and installing cylinder head“ |

| q | Before installing, insert washers in cylinder head → Item. |

| 4 - | Washer |

| q | For cylinder head bolts |

| 5 - | Hydraulic bucket tappet |

| q | Checking → Chapter |

| q | Removing and installing → Chapter „Removing and installing camshaft“ |

| q | Do not interchange (mark allocation) |

| q | Place down with contact surface facing downwards |

| q | Before installing check camshaft axial clearance → Fig. |

| q | Lubricate contact surface |

| 6 - | Valve cotters |

| 7 - | Valve spring plate |

| 8 - | Valve spring (outer) |

| q | Removing and installing with cylinder head installed → Chapter „Renewing valve stem oil seals“ |

| q | Remove and install with cylinder head removed using valve spring compressor -2037- |

| 9 - | Valve spring (inner) |

| q | Removing and installing with cylinder head installed → Chapter „Renewing valve stem oil seals“ |

| q | Remove and install with cylinder head removed using valve spring compressor -2037- |

| 10 - | Valve stem oil seal |

| q | Renewing → Chapter |

| 11 - | Valve guide |

| q | Checking → Chapter |

| 12 - | Unit injector |

| q | Removing and installing → Rep. Gr.23 |

| 13 - | Cylinder head |

| q | Machining valve seats → Chapter |

| 14 - | Oil seal |

| q | Renewing → Chapter |

| 15 - | Valves |

| q | Checking → Chapter |

| q | Valve dimensions → Chapter |

| q | Do not machine; only grinding in is permitted |

| 16 - | Bearing shell |

| q | Note installation position |

| q | Do not interchange used bearing shells (mark positions) |

| q | Make sure that the retaining lugs are correctly seated in the bearing caps and the cylinder head |

| 17 - | Camshaft |

| q | Check radial clearance with Plastigage |

| q | Radial clearance: wear limit: 0.11 mm |

| q | Runout: max. 0.01 mm |

| q | Checking axial clearance → Fig. |

| q | Removing and installing → Chapter |

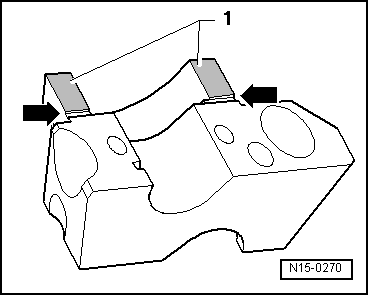

| 18 - | Bearing caps |

| q | Installation sequence → Chapter „Removing and installing camshaft“ |

| q | Bearing cap 4 is marked as bearing cap “5”. |

| q | Apply sealant to bearing caps 1 and 4 → Fig. |

| 19 - | 8 Nm + 90° (1/4 turn) further |

| q | Renew |

Note

Note

|

|