| Possible deviation from specification | Possible causes of fault | Fault elimination |

| l

| High pressure increases above specification |

| l

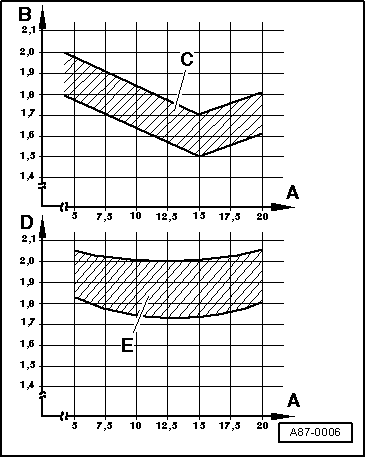

| Low pressure quickly drops to value in graph or below |

| l

| Required cooling output is not attained |

| Constriction or obstruction in refrigerant circuit | | –

| Run hand over refrigerant circuit to check for differences in temperature |

| l

| If difference in temperature is found at one component: |

| –

| Renew hose or pipe if kinked or constricted. |

| –

| In the event of clogging, clean refrigerant circuit (flush with refrigerant R134a → Chapter or blow out with compressed air and nitrogen → Chapter). |

| –

| Clean refrigerant circuit (flush with refrigerant R134a → Chapter or blow out with compressed air and nitrogen → Chapter). |

|

| l

| High and low pressure normal at first |

| l

| After some time, high pressure increases above specification and |

| l

| low pressure drops to value in graph or below, |

| l

| Required cooling output is no longer attained |

| Moisture in refrigerant circuit | | –

| Check and if necessary renew reservoir (with dryer) and restrictor, then evacuate refrigerant circuit for min. 3 hours (see note) |

| –

| Clean refrigerant circuit (flush with refrigerant R134a → Chapter or blow out with compressed air and nitrogen → Chapter). |

|

| l

| High and low pressure normal at first. |

| l

| After lengthy operating period, low pressure drops excessively (evaporator ices up). |

| | |

Note

Note Note

Note Note

Note Note

Note