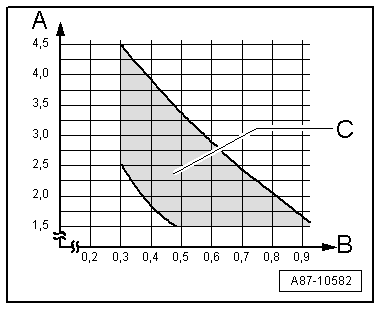

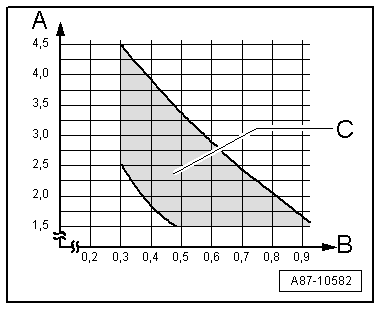

| Decreasing from initial pressure (on connecting pressure gauges) to value in graph |

| A - | Low pressure (measured at service connection) in bar absolute |

| B - | Control current for air conditioner compressor regulating valve -N280- in amps |

| C - | Permissible tolerance range |

Note | t

| In the event of a very high cooling output requirement (e.g. high ambient temperature and high fresh-air blower speed at low engine speed), the air conditioner compressor cannot initially set the pressure on the low-pressure end to the value -C- given in the graph (e.g. for a certain time after switching on the air conditioner). The air conditioner compressor is actuated with the maximum specified control current, however the delivery volume of the air conditioner compressor is no longer sufficient under these ambient conditions and at this engine speed to reduce the pressure on the low-pressure end to the value in the graph. One way of checking the control action of the air conditioner compressor under these conditions is to actuate the fresh-air blower with only approx. 40 % of the maximum voltage and to check the pressures at reduced fresh-air blower speed → Vehicle diagnostic tester („self-diagnosis“ or „Guided Fault Finding“ function for air conditioner) and → Heating, air conditioning; Rep. gr.87 or → Air conditioning; Rep. gr.87 (vehicle-specific workshop manual). |

| t

| Under unfavourable conditions (very high ambient temperatures, high humidity), pressure in high-pressure side may increase to max. 29 bar. |

| t

| The control current -B- is displayed in the measured value block of the operating and display unit for Climatronic air conditioning system -E87- or the operating and display unit, Climatronic control unit -J255-. |

| t

| The pressure in the refrigerant circuit measured by the high-pressure sender -G65- or the refrigerant pressure and temperature sender -G395- is displayed in the measured value block of the operating and display unit for Climatronic air conditioning system -E87- or the operating and display unit, Climatronic control unit -J255- → Vehicle diagnostic tester („self-diagnosis“ or „Guided Fault Finding“ function for air conditioner) and → Heating, air conditioning; Rep. gr.87 or → Air conditioning; Rep. gr.87 (vehicle-specific workshop manual). |

| t

| The low pressure settles as a function of the control current for the air conditioner compressor regulating valve -N280- within the air conditioner compressor output range in the tolerance band. |

| t

| Under unfavourable conditions (very high ambient temperatures, high humidity), the air conditioner compressor output may not always be sufficient to attain the specified value. |

| t

| If the compressor capacity utilisation is greater than 90 %, the pressure on the low-pressure end may be in excess of the tolerance range „C“ shown in the graph (the compressor output no longer suffices). |

| t

| The specified operating current for the regulating valve must be greater than 0.3 A to ensure reliable actuation of the regulating valve. |

| t

| „0 bar absolute pressure“ corresponds to an absolute vacuum. Normal ambient pressure corresponds to 1 bar absolute. On the scales of most pressure gauges, 0 bar corresponds to an absolute pressure of one bar (can be seen from „-1 bar“ mark below „0“). |

|

|

|

Note

Note

Note

Note Note

Note Note

Note Note

Note