A3 Mk1

| Adjusting differential |

| Special tools and workshop equipment required |

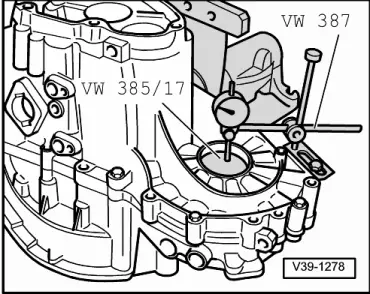

| t | End measuring plate -VW 385/17- |

| t | Universal dial gauge bracket -VW 387- |

| t | Press tool -VW 407- |

| t | Thrust plate -30 - 205- |

| t | Torque wrench -V.A.G 1331- |

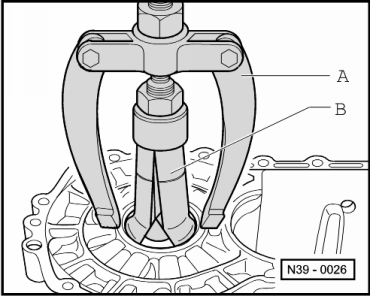

| t | -1-Internal puller -Kukko 21/7- |

| t | -4-Counter-support -Kukko 22/2- |

| t | Dial gauge |

Note

Note

|

|

|

| Measured value | 0.85 mm |

| + Preload (constant value) | 0.25 mm |

| Thickness of shim = | 1.10 mm |

|

|

| Shim | |

| Measured value (mm) | Thickness (mm) |

| 0.303…0.449 0.450…0.499 0.500…0.549 | 0.650 0.700 0.750 |

| 0.550…0.599 0.600…0.649 0.650…0.699 | 0.800 0.850 0.900 |

| 0.700…0.749 0.750…0.799 0.800…0.849 | 0.950 1.000 1.050 |

| 0.850…0.899 0.900…0.949 0.950…0.999 | 1.100 1.150 1.200 |

| 1.000…1.049 1.050…1.099 1.100…1.149 | 1.250 1.300 1.350 |

| 1.150…1.199 | 1.400 |

Note

Note

|