A3 Mk1

|

| Special tools and workshop equipment required |

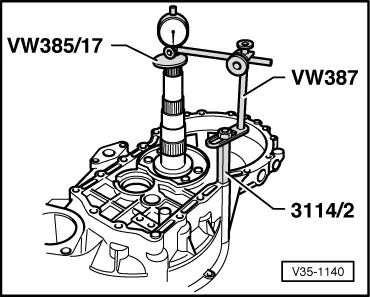

| t | Universal dial gauge bracket -VW 387- |

| t | End measuring plate -VW 385/17- |

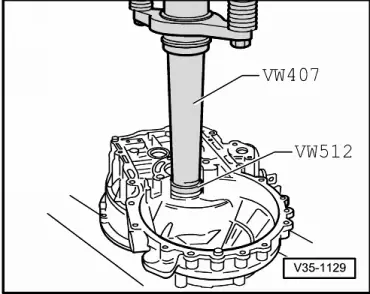

| t | Thrust pad -VW 512- |

| t | Straightening tool -3114/2- |

| t | Press tool -VW 407- |

| t | Torque wrench -V.A.G 1331- |

| t | Dial gauge |

|

|

|

|

|

|

|

|

| Shim installed | 0.65 mm |

| + Measured value | 0.35 mm |

| + Preload (constant value) | 0.15 mm |

| Thickness of shim | 1.15 mm |

|

|

| Thickness (mm) | Part No. |

| 0.65 0.70 | 020 311 391 P 020 311 391 Q |

| 0.75 0.80 0.85 | 020 311 391 020 311 391 A 020 311 391 B |

| 0.90 0.95 1.00 | 020 311 391 C 020 311 391 D 020 311 391 E |

| 1.05 1.10 1.15 | 020 311 391 F 020 311 391 G 020 311 391 H |

| 1.20 1.25 1.30 | 020 311 391 J 020 311 391 K 020 311 391 L |

| 1.35 1.40 | 020 311 391 M 020 311 391 N |

|