A3 Mk1

| Dismantling and assembling output shaft (pinion shaft) |

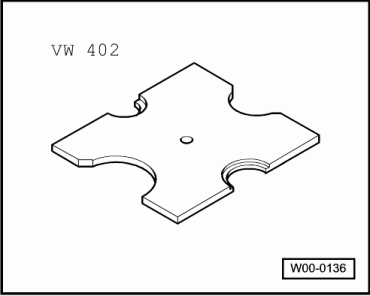

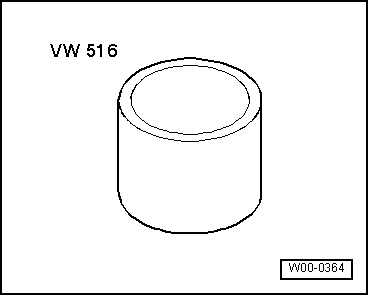

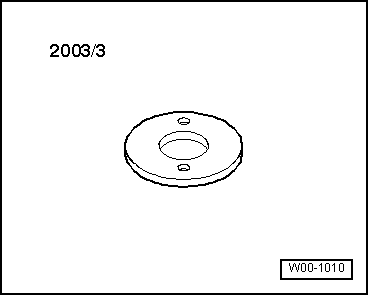

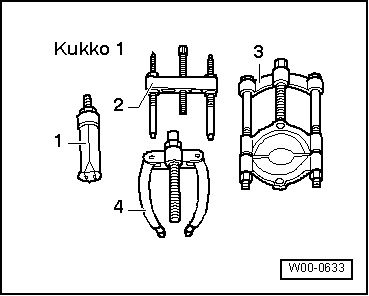

| Special tools and workshop equipment required |

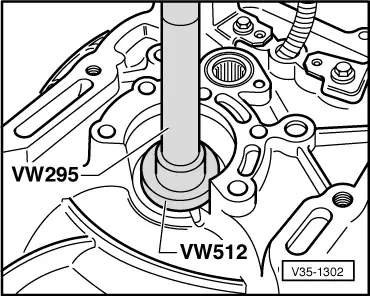

| t | Drift -VW 295- |

| t | Thrust pad -VW 512- |

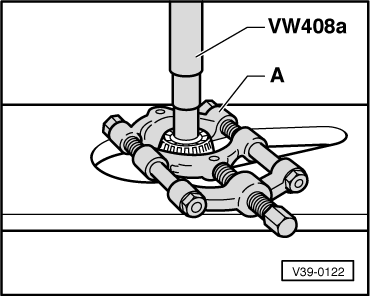

| t | Press tool -VW 408 A- |

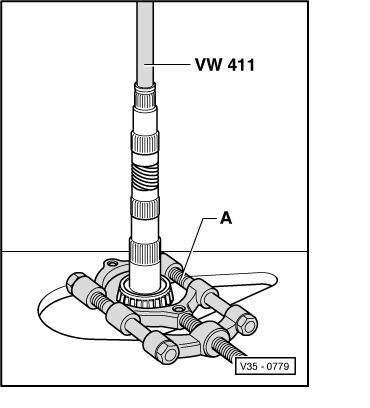

| t | Press tool -VW 411- |

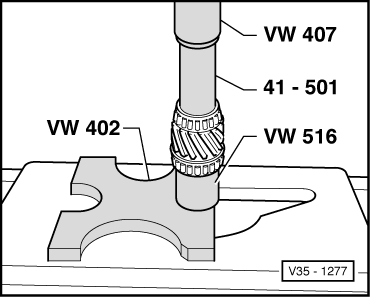

| t | Press tool -VW 407- |

| t | Drift sleeve -41 - 501- |

|

|

|

|

|

|

|

|

|

|

Note

Note| t | Refer to technical data → Chapter when installing new gears or a new output shaft. |

| t | Always renew both tapered roller bearings together. |

| t | Do not over-stretch circlips. Always renew circlips which have been damaged or over-stretched. |

| t | Carry out output shaft adjustment → Chapter if the clutch housing, output shaft (final drive gear set) or tapered roller bearings have been renewed. |

| 1 - | Gearbox housing cover |

| 2 - | 5th gear wheel retaining ring |

| 3 - | Thrust washer |

| 4 - | 5th gear wheel |

| q | Removing and installing → Chapter |

| 5 - | Gearbox housing |

| 6 - | Needle bearing |

| q | Removing and installing → Item |

| 7 - | 4th gear wheel retaining ring |

| 8 - | 4th gear wheel |

| q | Installation position → Fig. |

| 9 - | 3rd gear wheel retaining ring |

| q | Re-determining thickness → Chapter |

| 10 - | 3rd gear wheel |

| q | Installation position → Fig. |

| q | Adjusting axial clearance → Chapter |

| 11 - | 2nd speed selector gear |

| 12 - | Needle bearing for 2nd speed selector gear |

| q | Pulling off inner race → Chapter |

| q | Pressing on inner race → Chapter |

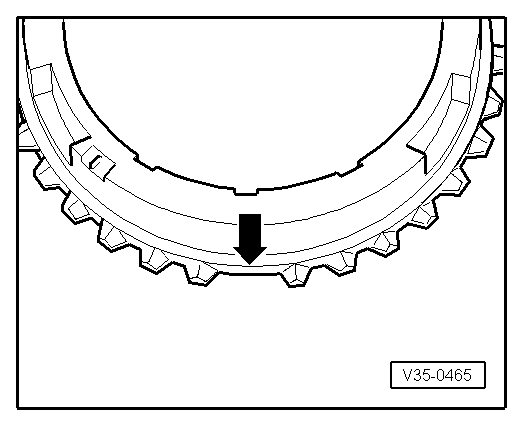

| 13 - | 2nd gear synchro-ring |

| q | Checking for wear → Fig. |

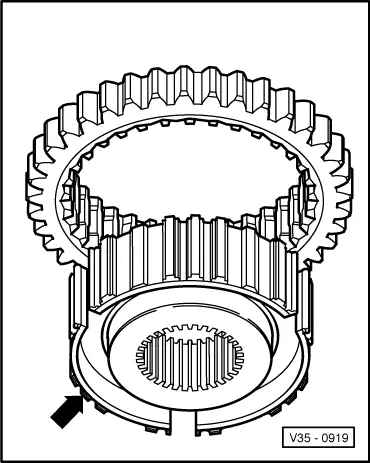

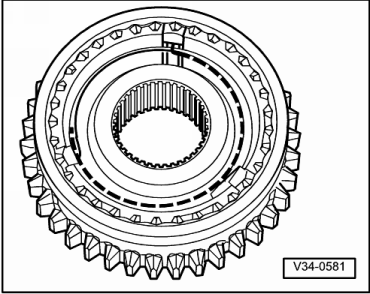

| 14 - | Locking collar with synchronising hub for 1st and 2nd gear |

| q | Assembling locking collar/synchronising hub → Fig. and → Fig. |

| q | Removing and installing → Chapter |

| 15 - | 1st gear synchro-ring |

| q | Checking for wear → Fig. |

| q | Identification → Fig. |

| 16 - | 1st speed selector gear |

| 17 - | Spring |

| 18 - | Locking collar |

| 19 - | Synchronising hub |

| 20 - | Locking pieces |

| q | 3x |

| 21 - | Needle bearing |

| q | For 1st gear |

| 22 - | Thrust washer |

| q | Installation position → Chapter |

| 23 - | Clutch housing |

| 24 - | Shim |

| q | For output shaft |

| q | Table of adjustments → Chapter |

| 25 - | Small tapered roller bearing outer race |

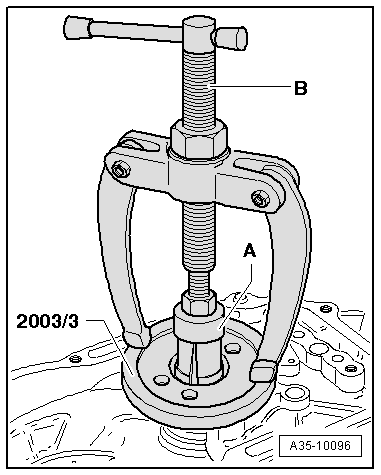

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 26 - | Small tapered roller bearing inner race |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 27 - | Output shaft |

| q | Is paired with final drive gear, always renew together as a set |

| q | Adjusting → Chapter |

| 28 - | Large tapered roller bearing inner race |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 29 - | Bearing mounting |

| q | With large tapered roller bearing outer race and stop for reverse gear wheel |

| q | Only renew outer race together with large tapered roller bearing and bearing mounting |

| 30 - | Bolt |

| q | 25 Nm and turn 90° further |

|

|

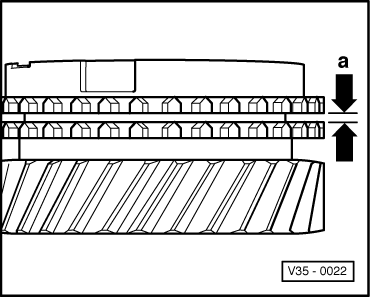

| Gap -a- | Installation depth | Wear limit |

| 1st and 2nd gear | 1.1 ... 1.7 mm | 0.5 mm |

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|