A3 Mk1

| Dismantling and assembling input shaft |

| Special tools and workshop equipment required |

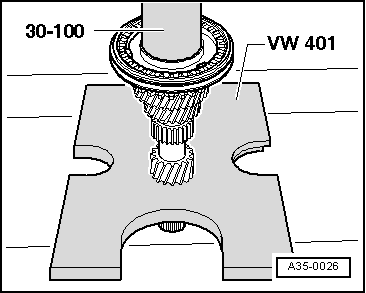

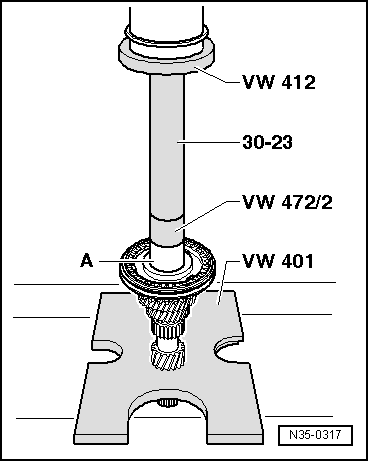

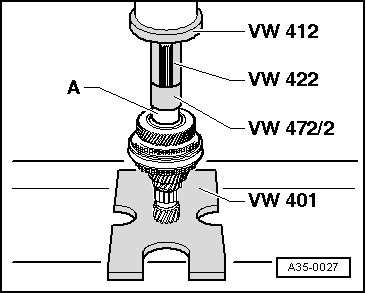

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

| t | Press tool -VW 412- |

| t | Tube -VW 415 A- |

| t | Tube -VW 422- |

| t | Spacer sleeve -VW 472/2- |

| t | Tube -VW 516- |

| t | Extension -30 - 23- |

| t | Drift sleeve -30 - 100- |

| t | Thrust piece -T10080- |

| t | Thrust piece -T10081- |

| t | 2010 Tube |

| t | Thrust block -T10083- |

| t | Thrust plate -T10084 A- |

| t | -1-Internal puller 30...37 mm, e.g. -Kukko 21/5- |

| t | -4-Counter support, e.g. -Kukko 22/1- |

Note

Note| t | Refer to technical data when installing new gears → Chapter. |

| t | Lubricate all bearings, selector gears and synchro-rings on input shaft with gear oil before installing. |

| t | Do not interchange synchro-rings. When re-using synchro-rings, always fit on the same selector gear. |

| 1 - | Circlip |

| q | Always renew |

| q | Determining thickness → Anchor |

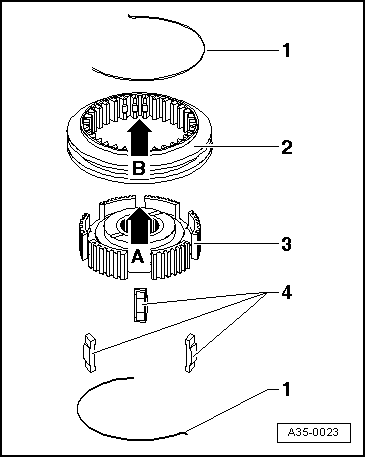

| 2 - | Locking collar with synchronising hub for 5th gear |

| q | Removing and installing → Chapter |

| q | Dismantling → Fig. |

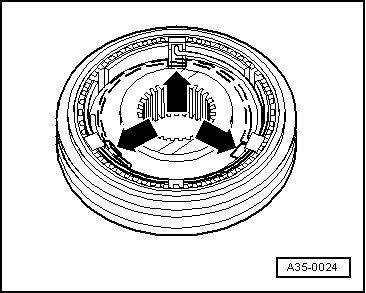

| q | Assembling 5th gear locking collar/synchronising hub → Fig. → Fig. |

| q | Installation position → Fig. |

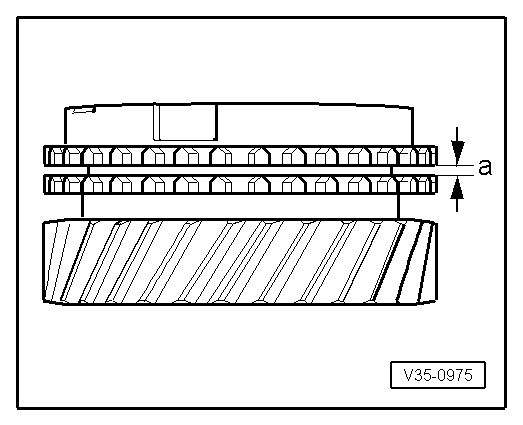

| 3 - | 5th gear synchro-ring |

| q | Checking for wear → Fig. |

| 4 - | 5th speed selector gear |

| 5 - | Needle bearing |

| q | For 5th gear |

| q | Renew together with → Item |

| 6 - | Sleeve |

| q | For 5th gear needle bearing |

| q | Renew together with → Item |

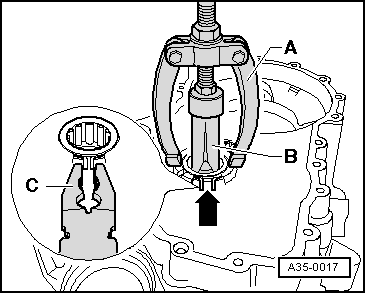

| q | Press off with bearing mounting/grooved ball bearing → Fig.. |

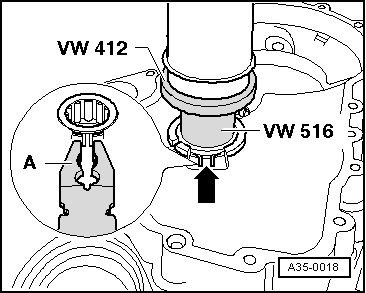

| q | Pressing on → Fig. |

| 7 - | Gearbox housing |

| 8 - | Bearing mounting with grooved ball bearings |

| q | Only renew grooved ball bearings together with bearing mounting. |

| q | If bearing mounting is separated from gearbox housing, it must always be renewed |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 9 - | Input shaft |

| 10 - | Needle bearing |

| q | For 3rd gear |

| 11 - | 3rd speed selector gear |

| 12 - | 3rd gear synchro-ring |

| q | Checking for wear → Fig. |

| 13 - | Locking collar with synchronising hub for 3rd and 4th gear |

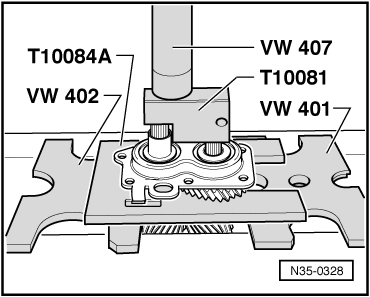

| q | Press off with 3rd speed selector gear → Fig. |

| q | Dismantling → Fig. |

| q | Installation position: Locking collar/synchronising hub → Fig. |

| q | Assembling → Fig. |

| q | Pressing on → Fig. |

| 14 - | 4th gear synchro-ring |

| q | Checking for wear → Fig. |

| 15 - | 4th speed selector gear |

| 16 - | Sleeve |

| q | For 4th gear needle bearing |

| q | Renew together with → Item |

| q | Press off with 3rd speed selector gear → Fig. |

| q | Pressing on → Fig. |

| 17 - | Needle bearing |

| q | For 4th gear |

| q | Renew together with → Item |

| 18 - | Thrust washer |

| 19 - | Inner race for roller bearing |

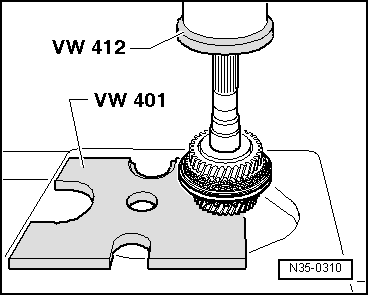

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 20 - | Circlip |

| q | Renew |

| q | Determining thickness → Fig. |

| 21 - | Roller bearing |

| q | With circlip |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| q | Installation position: Circlip in bearing faces towards input shaft |

| 22 - | Clutch housing |

| 23 - | Spring |

| q | Installation position → Fig. |

| 24 - | Locking collar for 3rd and 4th gear |

| 25 - | Synchronising hub for 3rd and 4th gear |

| 26 - | Locking pieces (3x) |

| 27 - | Spring |

| q | Installation position → Fig. |

| 28 - | Locking pieces (3x) |

| 29 - | 5th gear synchronising hub |

| 30 - | 5th gear locking collar |

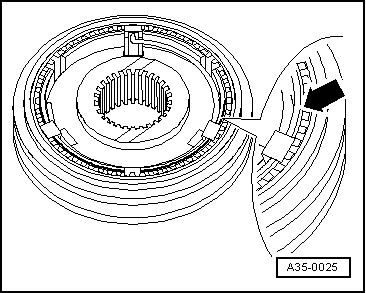

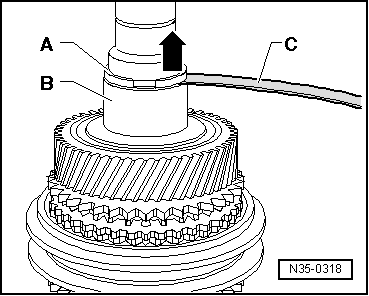

| 31 - | Check ring |

| q | Prevents locking pieces from moving out |

| q | Removing → Fig. |

| q | Installing → Fig. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Gap “a” | Installation depth | Wear limit |

| 3rd, 4th and 5th gear | 1.1 ... 1.7 mm | 0.5 mm |

|

|

|

|

|

|

Note

Note

|

|