| –

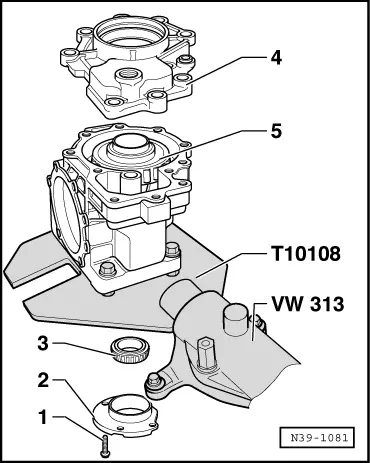

| Insert bevel gear with input shaft -5- into final drive housing. |

| –

| Fit tapered roller bearing inner race -3- onto bevel gear with input shaft as far as stop. |

| –

| Fit 1.75 mm shim in seat of small tapered roller bearing outer race (S2 side) in small cover -2-. |

| For measurement purposes a shim S2 with a thickness of 1.75 mm is fitted provisionally. This is referred to in the following as S2*. S2* is replaced with the final shim S2 after determining backlash. |

| –

| Insert small cover and tighten bolts to torque → Item. |

Note | On some gearboxes shim S1 is fitted between oil deflector plate and large cover. On these gearboxes the oil deflector plate must be removed and a provisional shim S1 fitted, which corresponds to the thickness of the oil deflector plate (e.g. 0.75 mm); Part No. → Electronic parts catalogue, ETKA. |

| –

| Install large cover with large tapered roller bearing outer race but without O-ring, flange shaft oil seal and without shim S1. |

| –

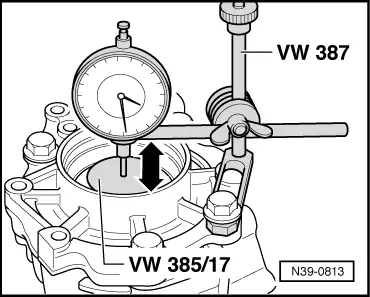

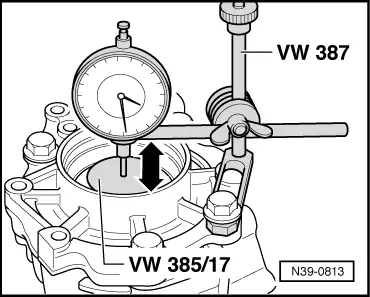

| Press bevel gear with input shaft towards large cover and turn eight times. |

| –

| Press bevel gear with input shaft towards outer race for small tapered roller bearing and turn eight times. |

|

|

|

Note

Note

Note

Note