A3 Mk1

|

|

|

Note

Note

|

|

|

|

|

|

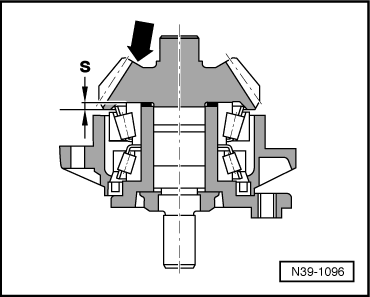

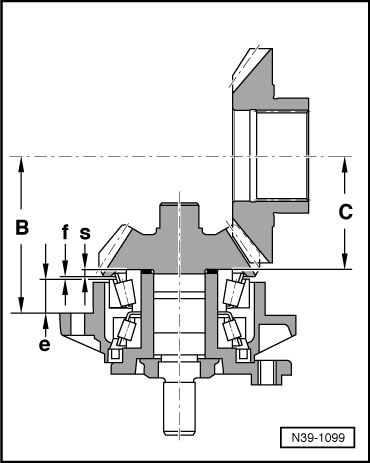

| Noted offset dimension -s- | 3.95 mm |

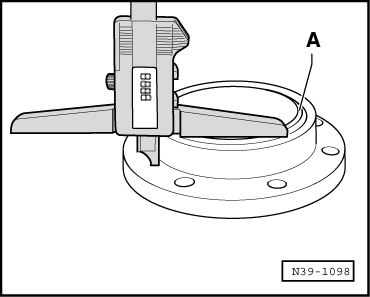

| Gap -f- as determined with feeler gauge | + 0.95 mm |

| Dimension -e- as determined with depth gauge | + 20.10 mm |

| Meshing dimension “C” with shaft bevel gear tolerance dimension “D” (C + D) | + 65.60 mm |

| Dimension -B- | = 90.60 mm |