-

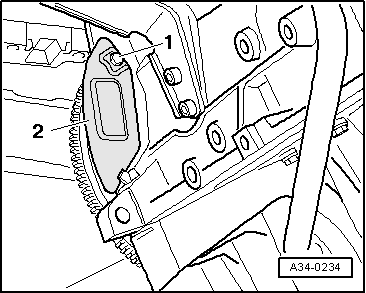

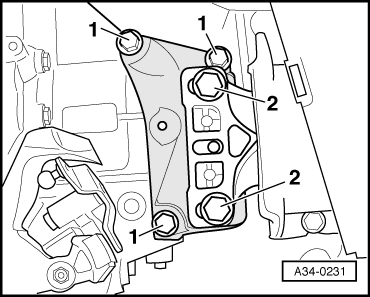

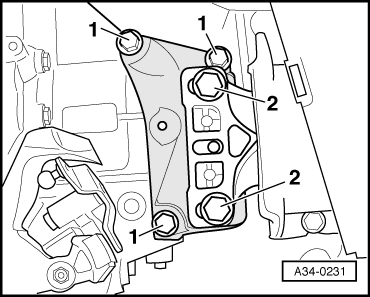

‒ → Bolt pendulum support onto gearbox -arrows B-

(40 Nm +1/4turn = 90°).

-

‒ Then bolt pendulum support onto subframe -arrow A-

(20 Nm +1/4turn = 90°).

-

‒ Install exhaust system and align stress-free:

=> 4-Cylinder TDI®engine; Repair group 26; Removing and installing parts of exhaust system; Stress-free alignment of exhaust system - vehicles with front-wheel drive

-

‒ Bolt drive shafts to gearbox

(M10 Bolts; 77 Nm)

-

‒ Fit right drive shaft guard (35 Nm).

The remaining installation steps are carried out in the reverse sequence.

-

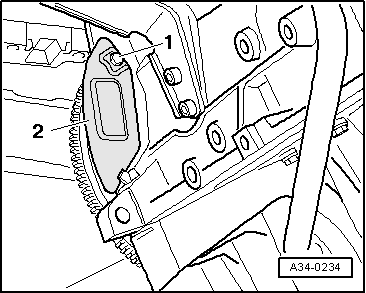

‒ Attach selector cables to gearbox and adjust=>Page34-20.

-

‒ Bleed clutch system=>Page 30-20.

-

‒ Electrical connections and routing:

=> Current flow diagrams, Electrical fault finding and Fitting locations binder

Note:

After connecting battery, activate the electrical equipment (radio, clock, electric window lifters) as described in the owner's manual.

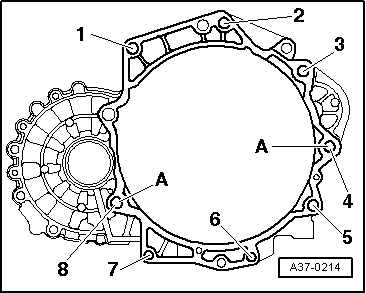

Tightening torques

|

|

|---|

|

Components

|

Nm

|

|

Bolts/nuts

|

M6

|

10

|

|

|

M8

|

20

|

|

|

M10

|

45

|

|

|

M12

|

65

|

|

Except for the following:

|

|

|

|

Selector cable support bracket to gearbox

|

23

|

|