A3 Mk1

| Removing gearbox |

|

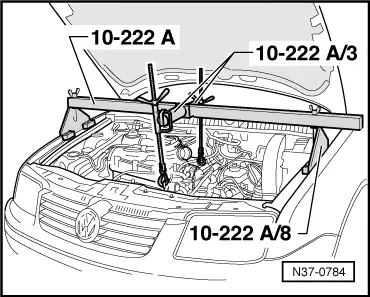

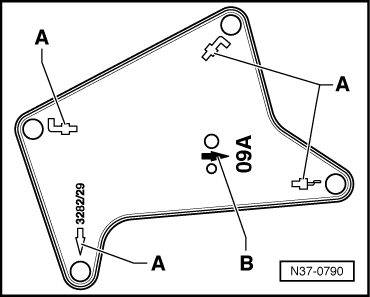

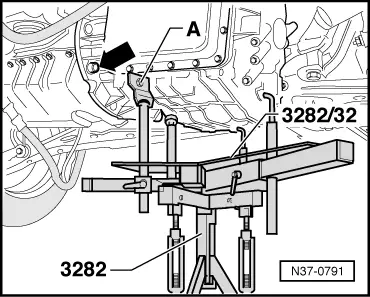

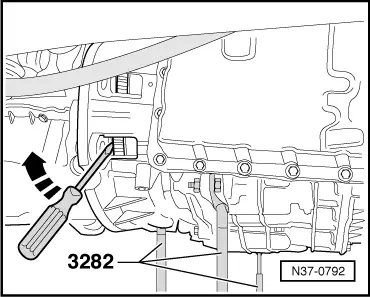

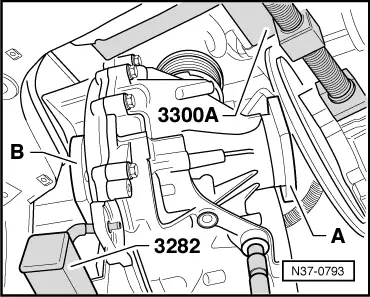

| t | Gearbox support -3282- |

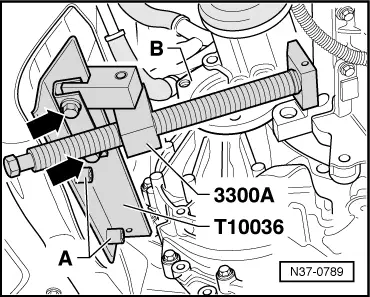

| t | Engine support -3300 A- |

| t | Support -T10036 A- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution