A3 Mk1

|

Removing and installing cylinder head

Removing cylinder head

|

|

|

|

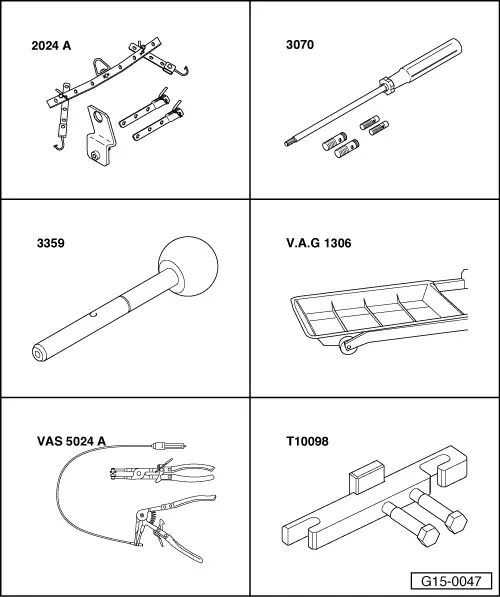

Special tools and workshop equipment required

|

|

|

Procedure

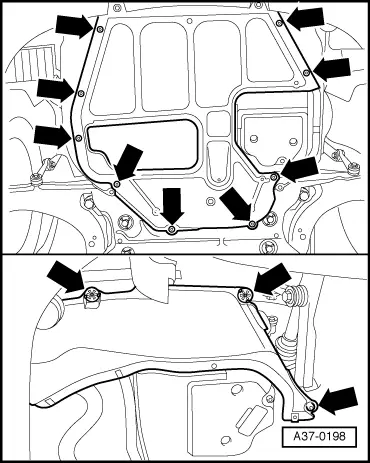

Note: All cable ties which are released or cut open when removing must be fitted in the same position when installing.

|

|

|

|

|

|

|

Important

Hot steam or hot coolant can escape when opening expansion tank. Cover cap with a cloth and open carefully.

|

|

|

|

|

|

|

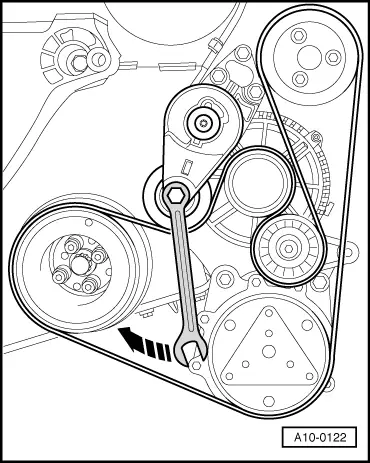

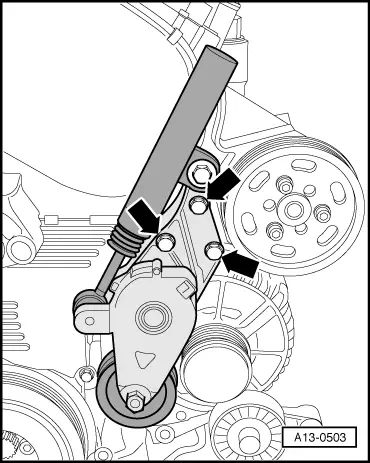

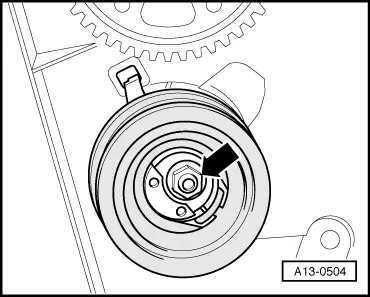

Note: Mark the running direction with chalk or a felt-tipped pen before removing the ribbed belt. If the belt runs in the opposite direction when it is refitted, this can cause breakage.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

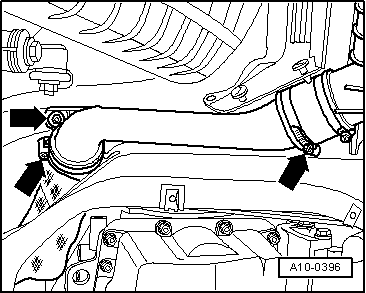

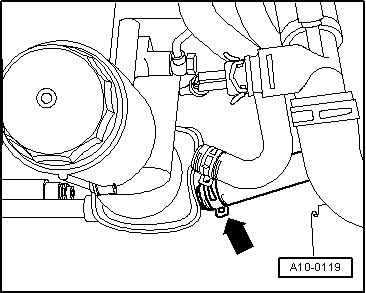

Note: The isolating element in front exhaust pipe must not be deflected more than 10° to avoid damage..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

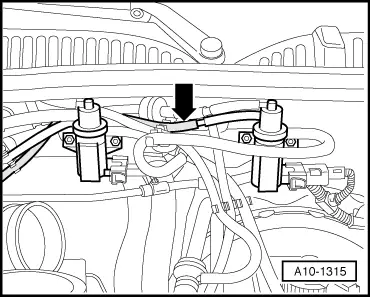

Note: Always remove complete pipe set. Use injector pipe spanner 3035.

|

|

|

|

|

|

|

|

|

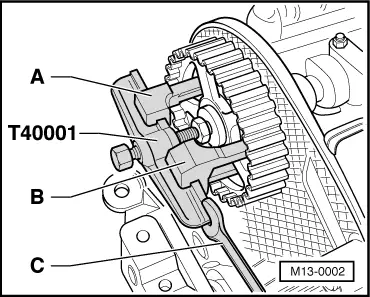

Note: Position crankshaft to TDC No. 1 cylinder 1 with engine removed. |

|

|

|

|

|

|

|

|

|

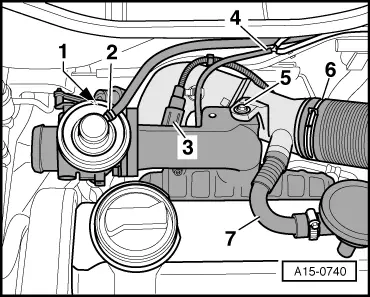

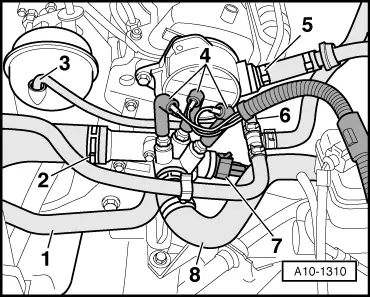

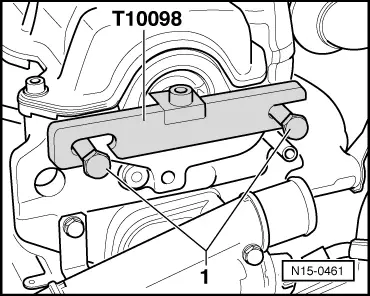

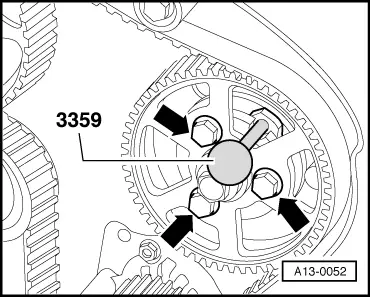

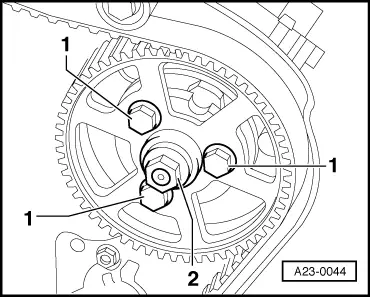

Note: → Never loosen the injection pump sprocket central nut -2-. Otherwise the injection pump basic setting is incorrectly adjusted and cannot be corrected again using workshop equipment. |

|

|

|

|

|

|

|

|

|

|

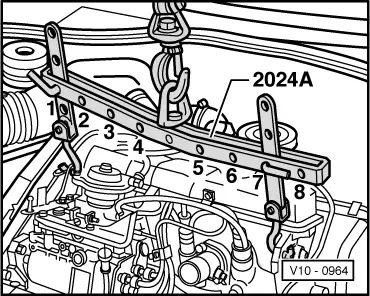

Important

The hook attachments and locating pins on the lifting tackle must be secured with locking pins. Note: In addition, tie intake manifold to lifting tackle eye in order to obtain a stable centre of gravity position for the cylinder head.

|