|

Installing

Installation is carried out in the reverse order; note the following:

Notes:

-

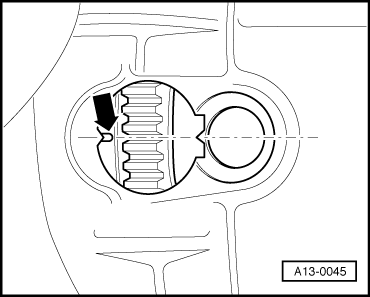

◆ When installing the camshaft, No. 1 cylinder cams must point upwards.

-

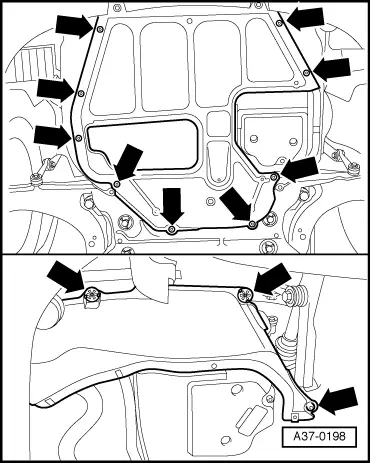

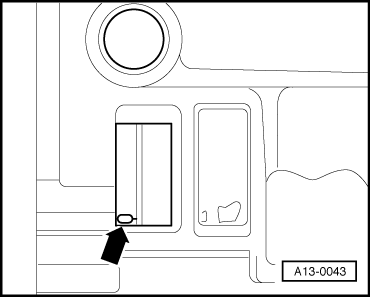

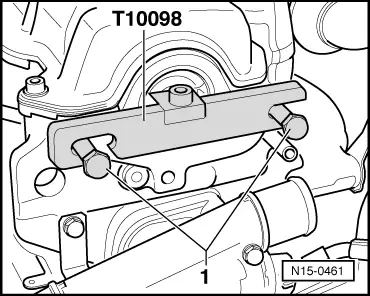

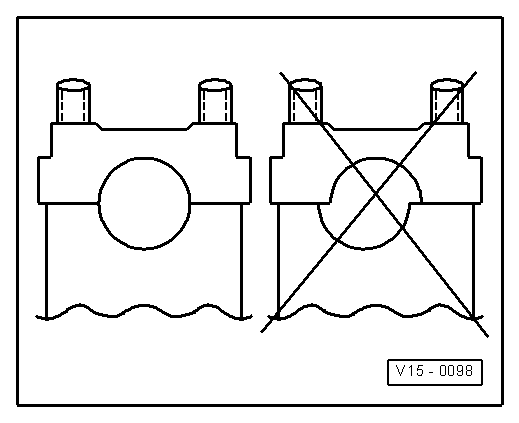

◆ → Before installing bearing caps, note bore offset and determine fitting location.

-

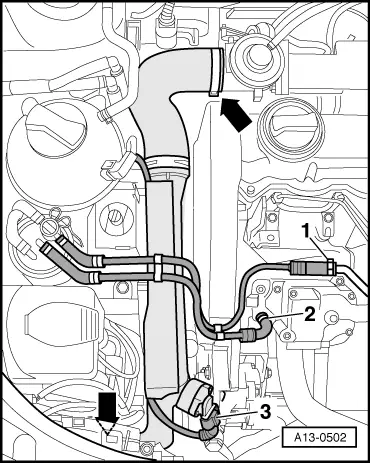

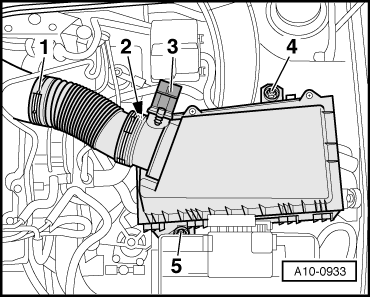

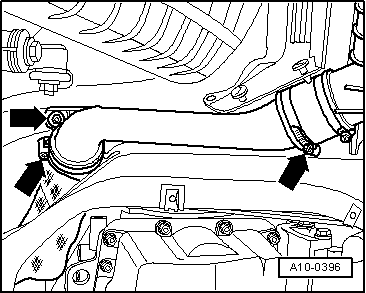

◆ Hose connections and hoses for charge air system must be free of oil and grease before assembly.

-

◆ Secure all hose connections with the correct hose clamps (same as original equipment):

=> Parts List

-

‒ Oil camshaft running surfaces.

-

‒ Tighten bearing caps 2 and 4 alternately and diagonally to 20 Nm.

-

‒ Install bearing caps 5, 1 and 3 and also tighten to 20 Nm.

-

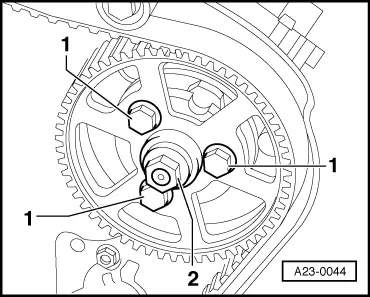

‒ Attach camshaft sprocket and hand-tighten.

-

‒ Install cylinder head cover => Page 15-11.

-

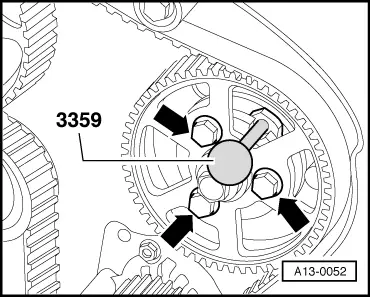

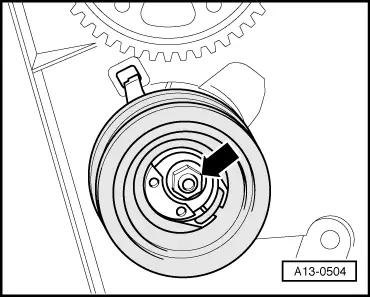

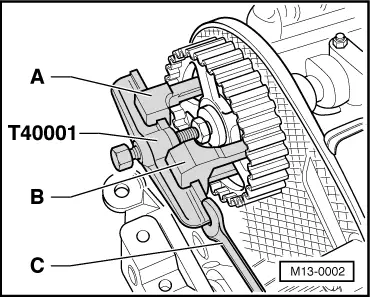

‒ Install toothed belt (adjust valve timing) => Page 13-31.

Notes:

-

◆ Note all instructions on removing and installing the toothed belt .

-

◆ After installing the camshaft, wait for about 30 minutes before starting the engine. Hydraulic valve compensation elements have to settle (otherwise valves will strike pistons).

-

◆ After working on the valve gear, turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated.

Tightening torque

|

|

|---|

|

Component

|

|

Nm

|

|

Bearing cap to cylinder head

|

|

20

|

|