A3 Mk1

|

|

|

Removing

|

|

|

|

|

|

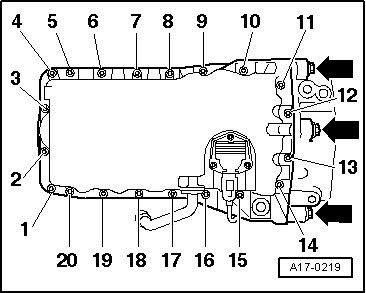

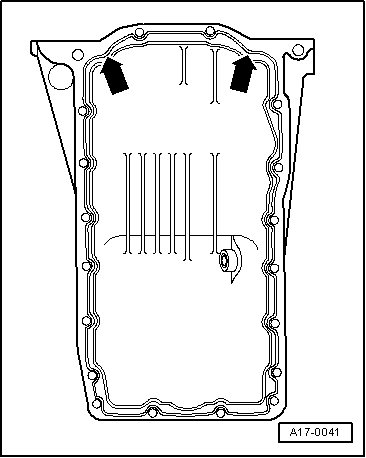

Note: Loosen and tighten oil pan bolts with jointed wrench 3185. Unscrew using socket attachment 3249.

|

|

|

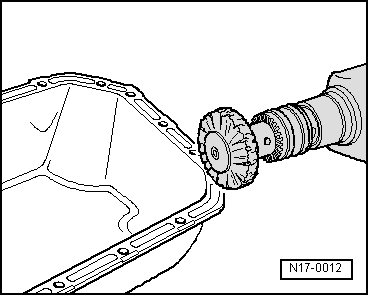

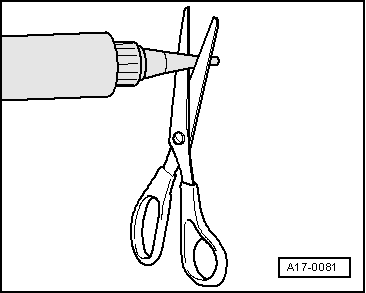

Important

Wear protective glasses.

|

|

|

|

Installing Installation is carried out in the reverse order; note the following:

|

|

|

Notes:

|