A3 Mk1

|

Removing and installing engine -vehicles with four-wheel drive-

Installing

Procedure

Installation is carried out in the reverse order; note the following: Notes:

=> Parts List

|

|

|

Notes:

|

|

|||||||||||||||||||

|

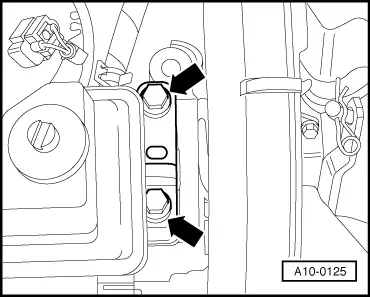

Vehicles with manual gearbox 02M: → Fastening engine to gearbox

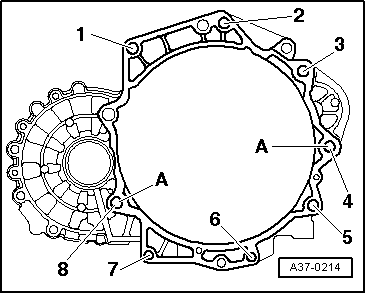

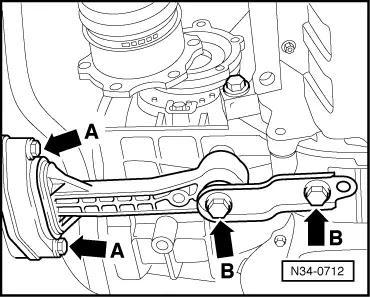

1) Bolt with threaded pin M8 2) Replace bolts A: Centring sleeves |

|

|

|

|

|

|

|

|

|

|

|

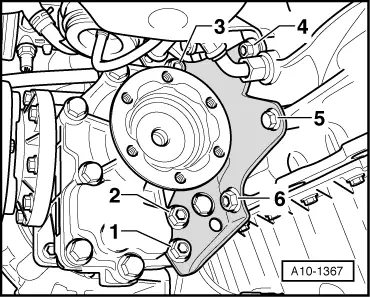

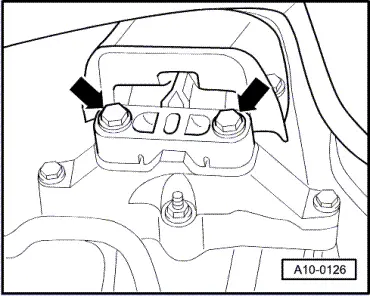

Note: The bolts are tightened to final torque only after adjusting the engine mounting => Page 10-85.

|

|

|

Important

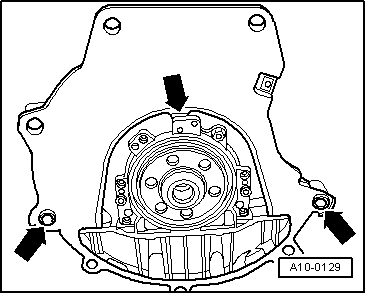

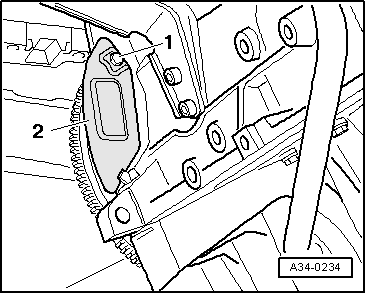

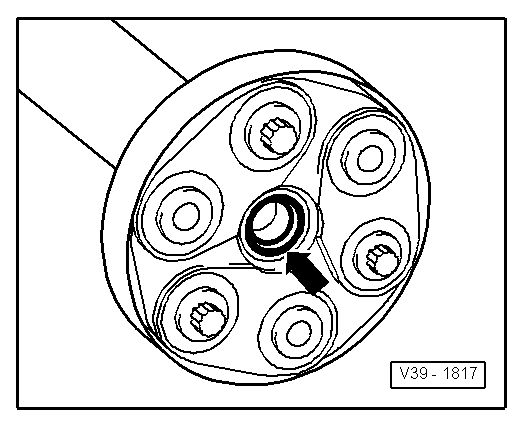

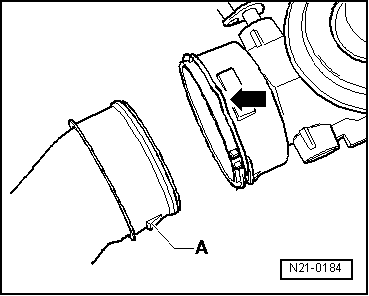

The sealing ring -arrow- in the flange of the propshaft may not be damaged when removing and installing the mechanical units of the engine/gearbox. If sealing ring is damaged propshaft must be replaced. |

|

|

=> 5 and 6-speed Manual Gearbox-02M Four-wheel Drive/Final Drives; Repair group 39

|

|

|

=> Running Gear, FWD and 4WD; Repair group 40

|

|

|

Important

The clutch pedal must not be operated before the clutch system has been bled.

|

|

||||||||||||||||||||||||||||||||||||||||||||

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder Notes:

=> Radio, Telephone and Navigation System; Repair group 91

Important

Do not use charging unit for boost starting. There is danger of damaging the vehicle control units.

Notes:

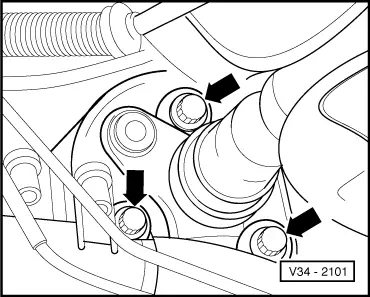

Tightening torques

1) Stretch bolts, replace 2) 90°corresponds to a quarter of a turn

| ||||||||||||||||||||||||||||||||||||||||||||