|

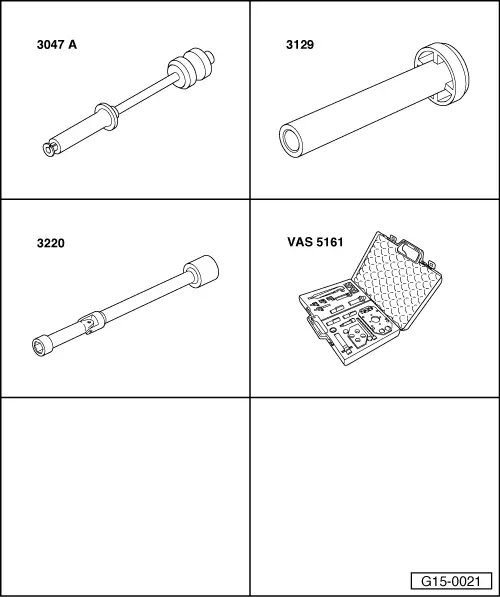

Special tools and workshop equipment required

-

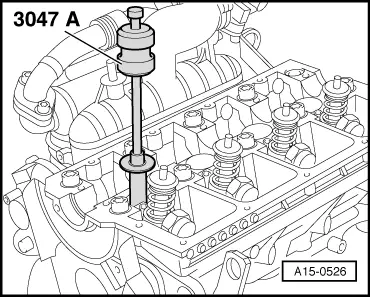

◆ Puller 3047 A

-

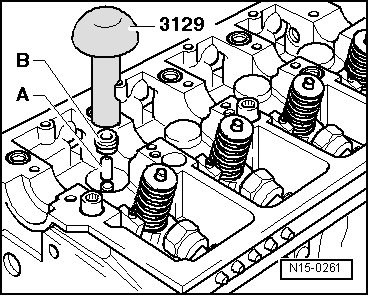

◆ Fitting tool 3129

-

◆ Flexible-head spanner 3220

-

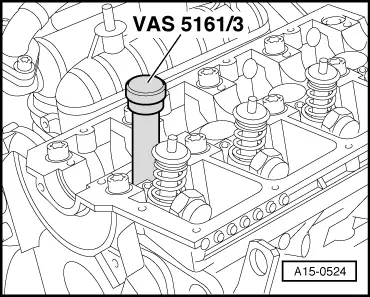

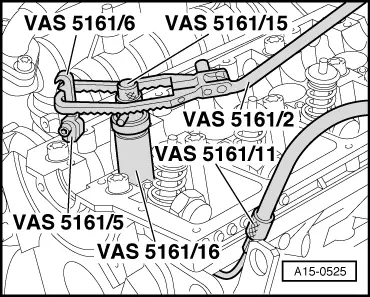

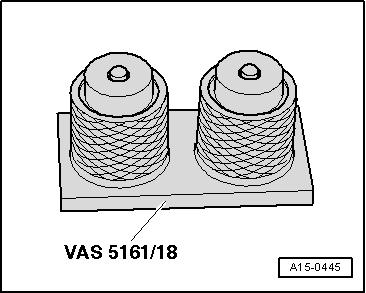

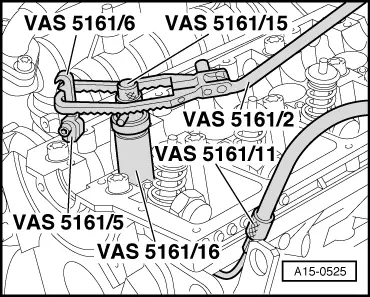

◆ Disassembly and assembly tool VAS 5161

Removing

-

● Cylinder head installed

Note:

When cylinder head was removed the valve stem seals can be replaced when using special tool 2037.

-

‒ Removing camshaft => page 15-100.

-

‒ Remove camshaft bearing shells from cylinder head.

Notes:

-

◆ Make sure that the camshaft bearing shells are not interchanged.

-

◆ Mark allocation of camshaft bearing shells on rear with a waterproof felt-tip pen.

-

◆ Make sure that the bucket tappets are not interchanged.

-

◆ Mark allocation of bucket tappets on rear with a waterproof felt-tip pen.

-

‒ Remove the bucket tappets from guides and put them down with the contact surface downwards.

|