A3 Mk1

|

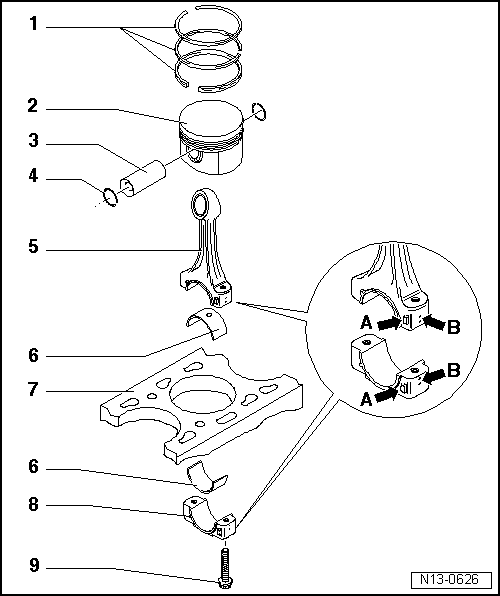

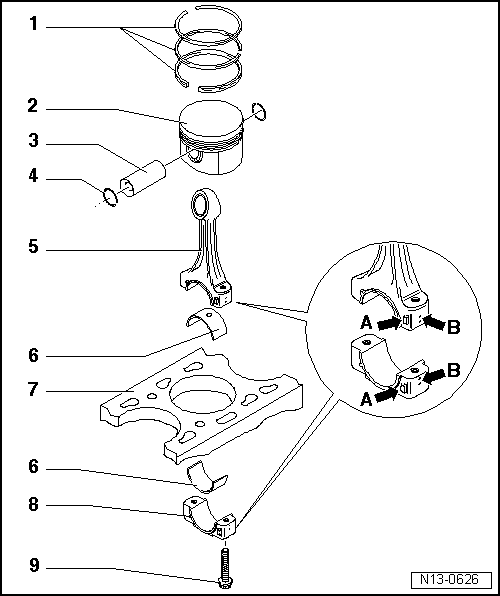

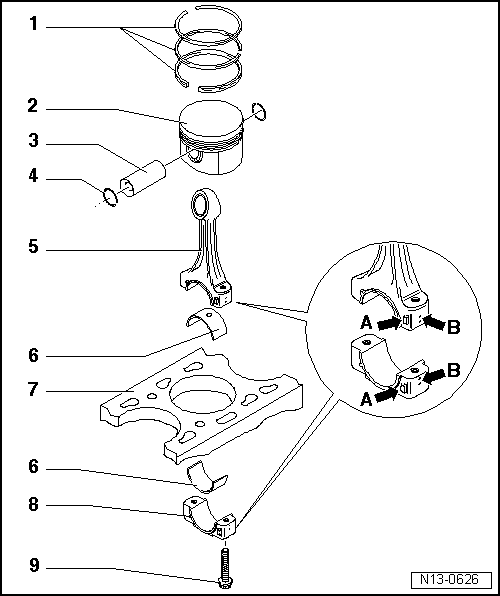

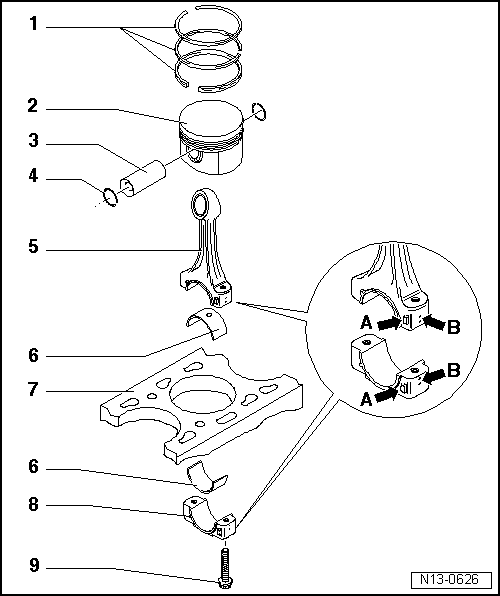

Dismantling and assembling pistons and conrods

Sawn conrods

|

|

|

|

Note: Oil spray jet and pressure relief valve => Fig.13-116

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

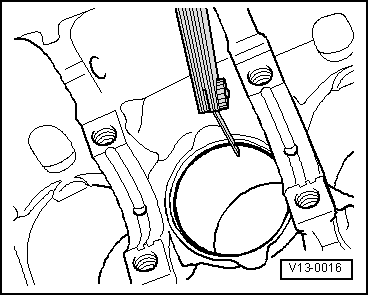

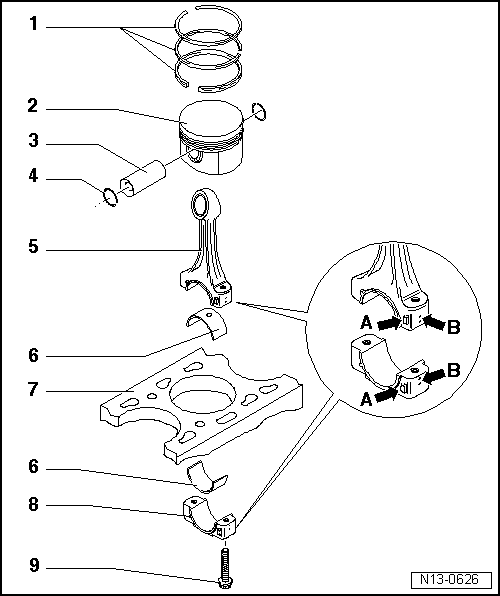

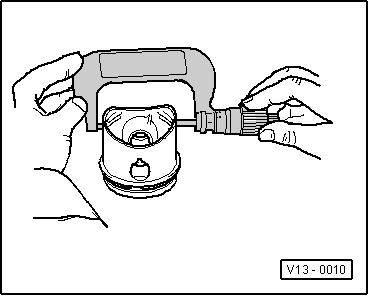

→ Fig. 2 Checking ring to groove play

|

|

|

|

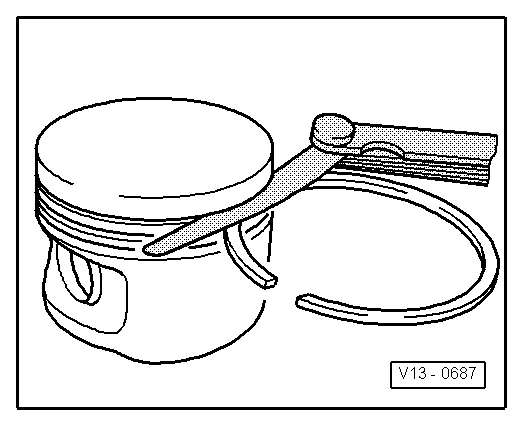

→ Fig.3 Piston installation position and arrangement of piston/cylinder

Pistons in cylinder 1 and 2: Large valve pocket for inlet valve towards flywheel side -arrows- Pistons in cylinder 3 and 4: Large valve pocket for inlet valve towards pulley side -arrows- Note: On new pistons the cylinder numbers are marked in colour on the piston crowns.

|

|

|

|

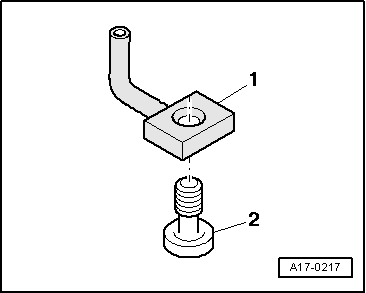

→ Fig. 4 Checking piston

|

|

|

|

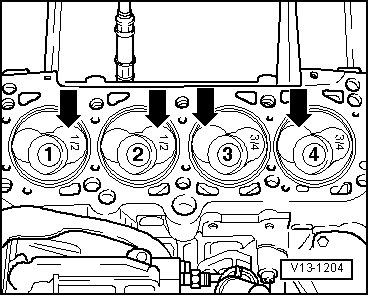

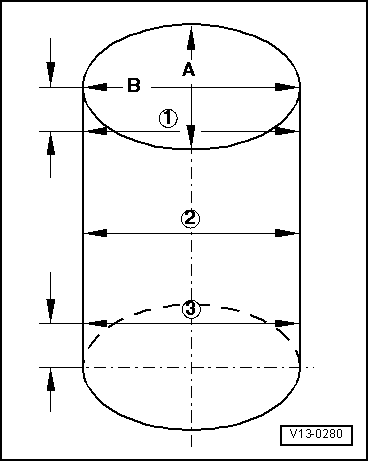

→ Fig. 5 Checking cylinder bores Special tools and workshop equipment required

|

|

|

|

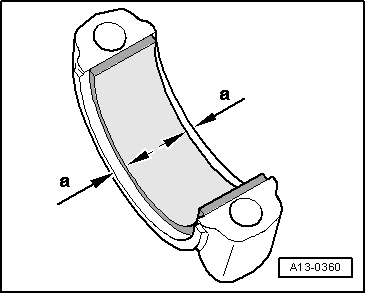

→ Fig.6 Installation position of bearing shell

|

|

|

|

→ Fig.7 Oil spray jet and pressure relief valve

|