|

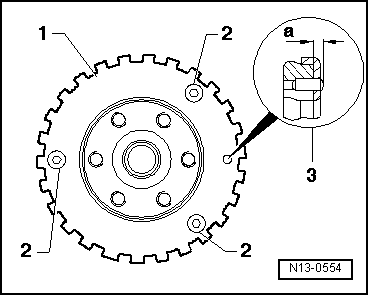

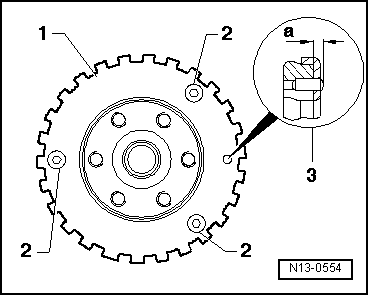

→ Fig.1 Removing and installing sender wheel

-

‒ Always renew sender wheel -2- if securing bolts -1- have been unscrewed.

Notes:

-

◆ If the securing bolts are tightened a second time, the seats for the countersunk bolt heads in the sender wheel will be distorted to such an extent that the bolt heads will come into direct contact with the crankshaft -3- (- arrows -) and the sender wheel will only fit loosely under the bolts.

-

◆ The mounting holes are asymmetrically spaced, so it is only possible to install the sender wheel in one position.

Tightening torque

|

|

|---|

|

Component

|

|

Nm

|

|

Sender wheel to crankshaft

|

|

10 + 90° 1)2)

|

1) Replace bolts

2) 90°corresponds to a quarter of a turn

|