A3 Mk1

|

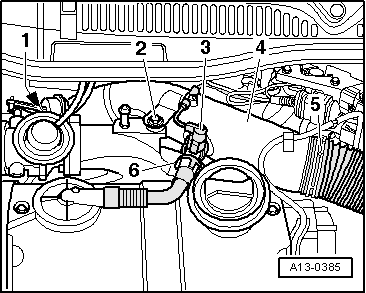

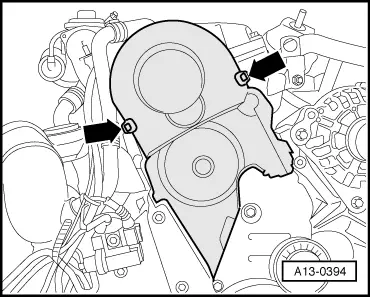

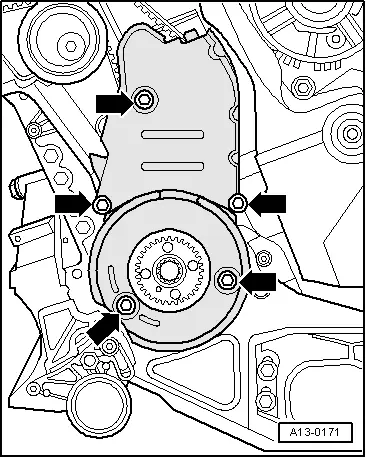

Toothed belt drive with hydraulically damped tensioning roller - Assembly overview

Removing and installing toothed belt

|

|

|

|

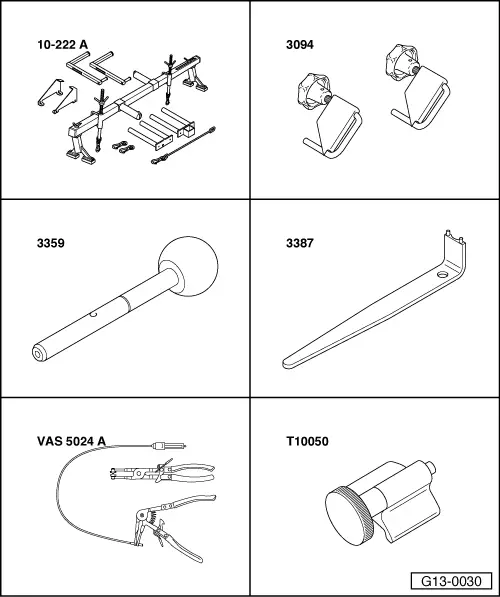

Special tools and workshop equipment required

|

|

|

=> Parts List |

|

|

|

Removing

|

|

|

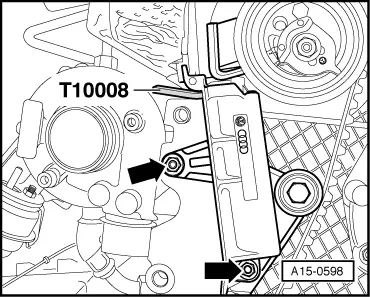

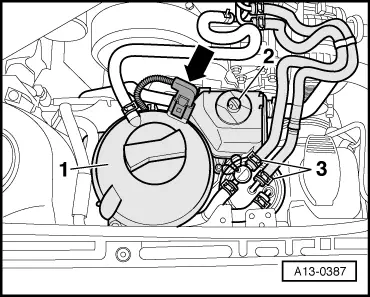

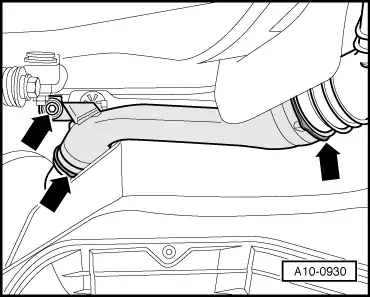

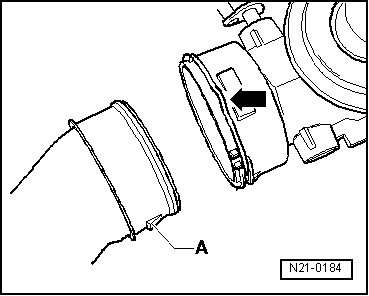

Note: For vehicles with four-wheel drive, the spring clamp is not accessible from above. To release the spring clamp, remove the air duct pipe from the right longitudinal member and the centre and right noise insulation.

|

|

|

|

|

|

Note: Close opening at refill reservoir with plug. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

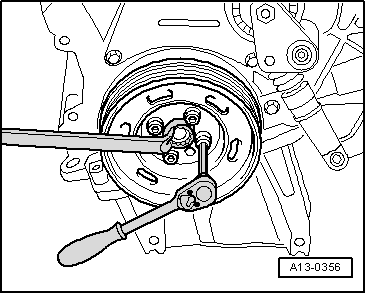

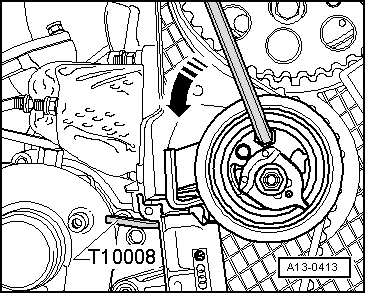

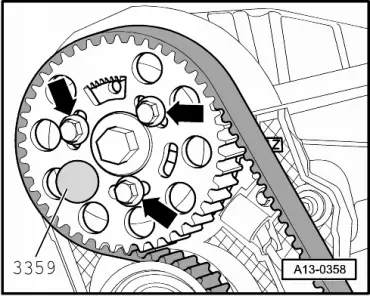

Note: To loosen and tighten the vibration damper counterhold with ring spanner on central bolt. |

|

|

|

|

|

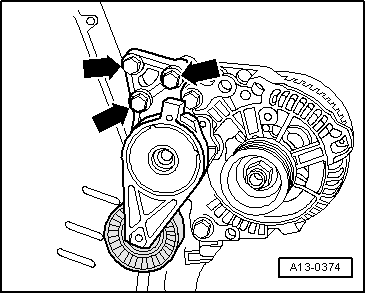

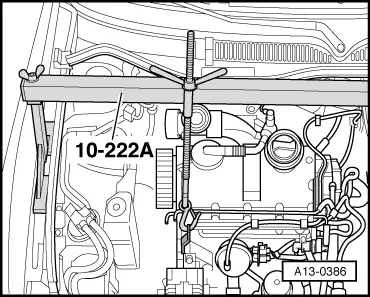

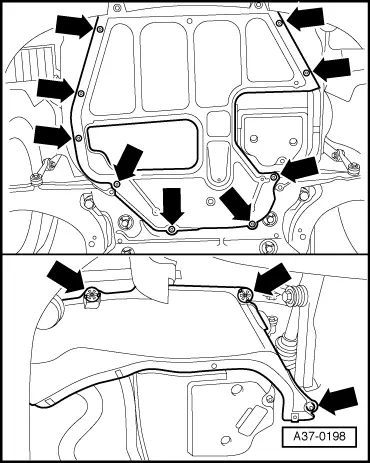

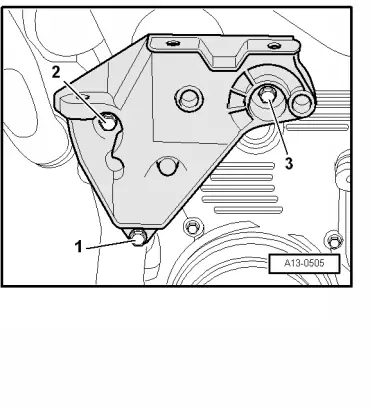

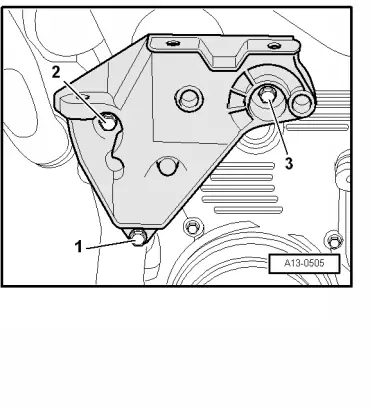

Note: To remove the bolts for the engine support, raise or lower the engine slightly as necessary using the spindles on engine support bracket 10-222A. |

|

|

|

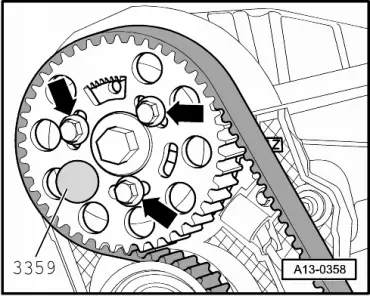

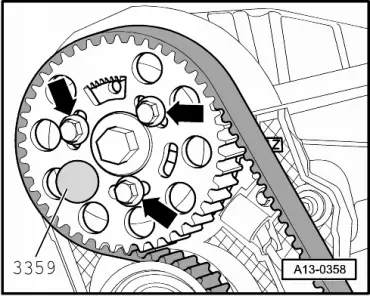

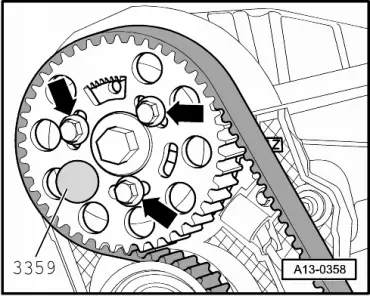

Important

The engine must only be turned at the crankshaft, in the direction of engine rotation (clockwise).

Notes:

|

|

|

Notes:

|

|

|

|

|

|

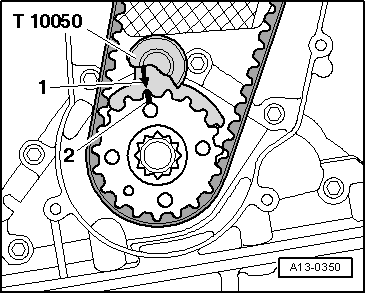

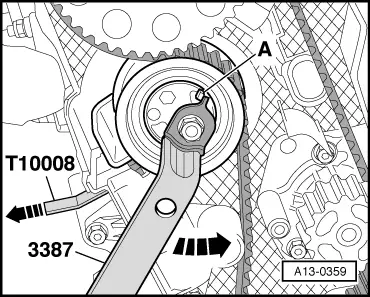

Notes:

|

|

|

|

|

|

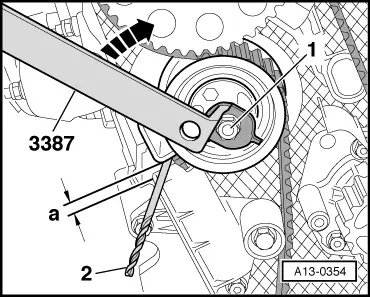

Note: Special tool Matra V/159 may be used in place of pin wrench 3387. |

|

|

|

|

|

|

|

|

|

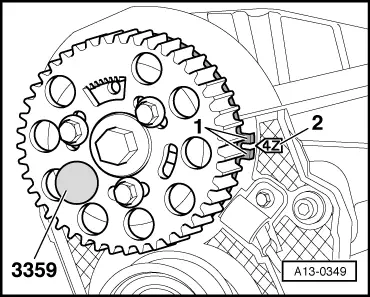

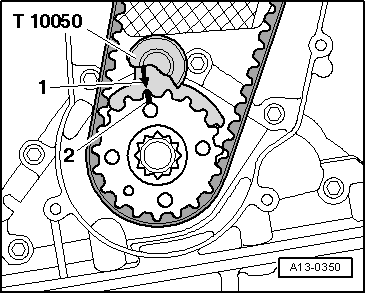

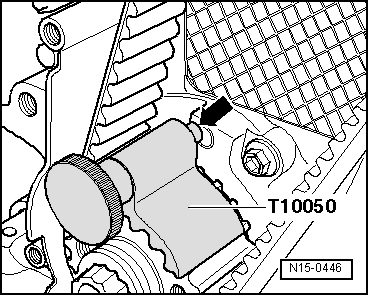

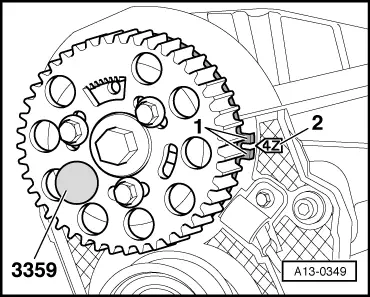

Checking the valve timing

Notes:

|

|

|

|

|

|

Notes:

|

|

|

|

If hub cannot be locked:

Important

The engine must only be turned at the crankshaft, in the direction of engine rotation (clockwise).

|

|

|

|

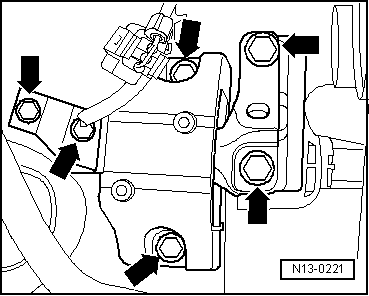

The remaining installation steps are carried out in the reverse sequence - note the following points: → Secure the engine support as follows:

|

|

||||||||||||||||||||||||||||||||||||||||||||

Tightening torques

1) 45°corresponds to an eighth of a turn 2) install using locking compound; => Parts List 3) Replace bolts 4) 90°corresponds to a quarter of a turn 5) Only tighten to final torque after adjusting the engine mounting=> Page 10-85

| ||||||||||||||||||||||||||||||||||||||||||||