A3 Mk1

|

|

|

|

|

|

|

|

|

|

|

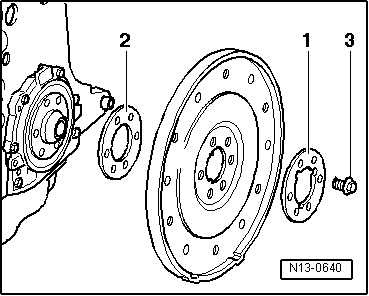

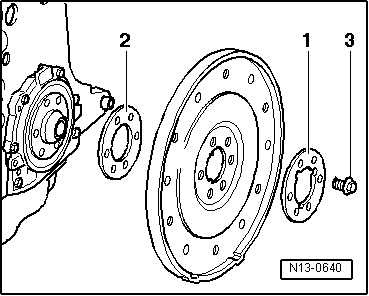

| Component | Nm | ||||

| Drive plate to crankshaft | 60 + 90° 1)2) | ||||

| |||||

|

|

|

|

|

|

|

|

|

|

|

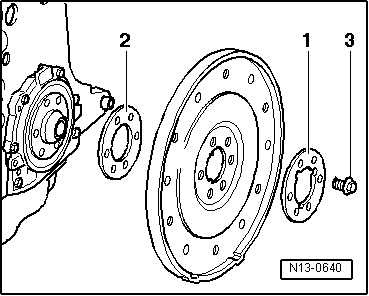

| Component | Nm | ||||

| Drive plate to crankshaft | 60 + 90° 1)2) | ||||

| |||||