A3 Mk1

|

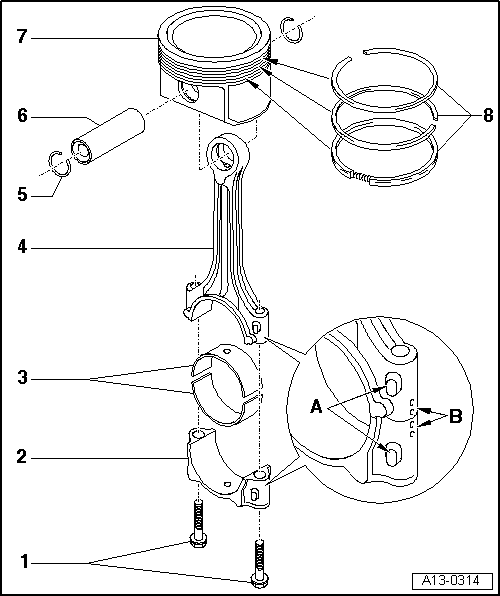

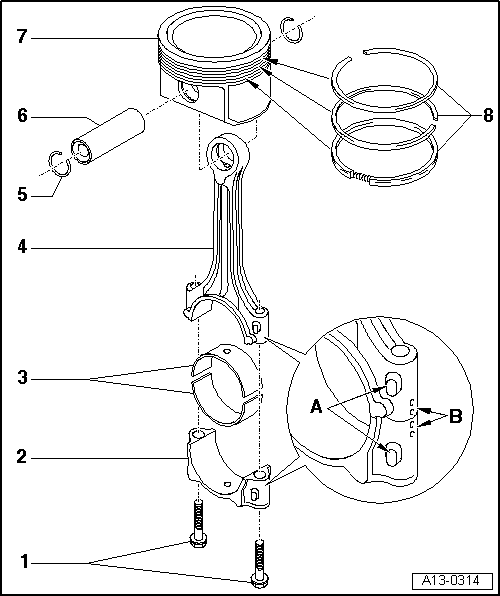

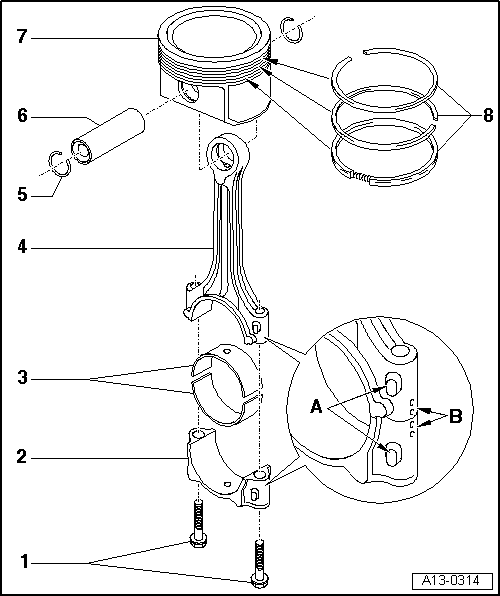

Dismantling and assembling pistons and conrods

Cracked conrods

|

|

|

|

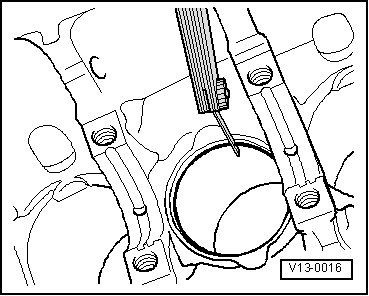

Note: Oil spray jet and pressure relief valve => Fig.13-88

|

|

|

|

|

|

|

|

|||||||||||||

|

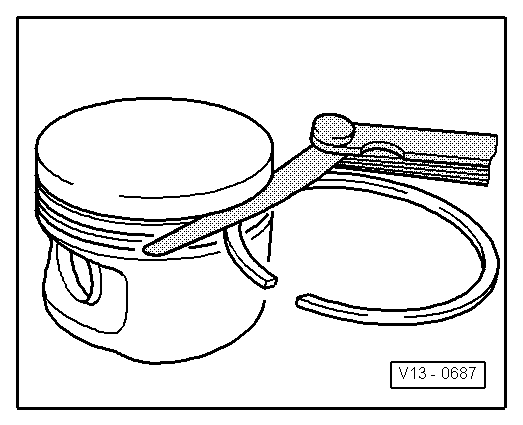

→ Fig. 2 Checking ring to groove play

|

|

|

|

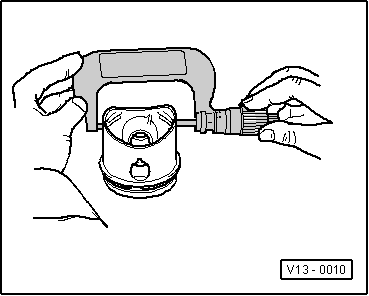

→ Fig. 3 Checking piston

|

|

|

|

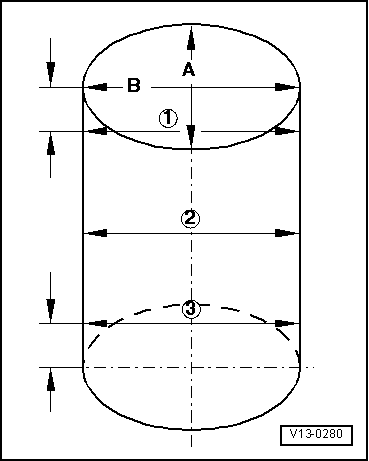

→ Fig. 4 Checking cylinder bores

|

|

|

|

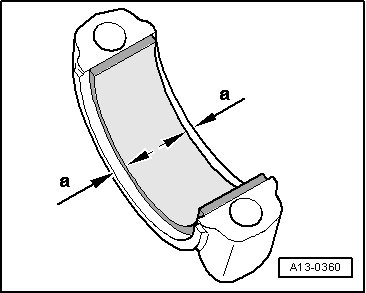

→ Fig.5 Installation position of bearing shell with cracked conrods

Note: The bearing shell with the oil bore must be inserted in the conrod. |

|

|

|

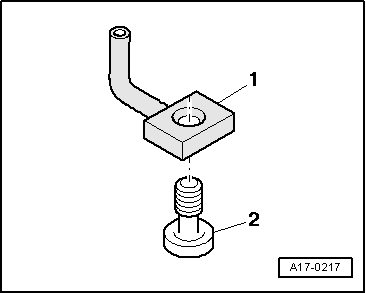

→ Fig.6 Oil spray jet and pressure relief valve

|