A3 Mk1

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

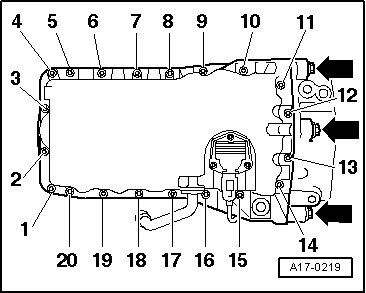

| Component | Nm |

| Sump to cylinder block | 15 |

| Sump to gearbox | 45 |

| Oil drain plug | 30 |

WARNING

WARNING