A3 Mk1

| Crankshaft - exploded view of components |

| 1 - | Thrust washers |

| q | For bearing No. 3 |

| q | Installation position: oil grooves face toward crank webs |

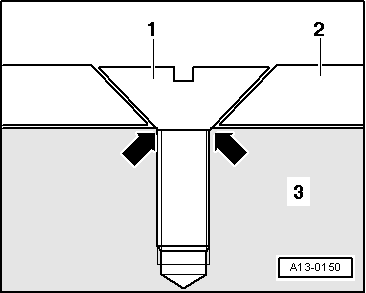

| 2 - | Bearing shell for cylinder block |

| q | With oil groove |

| q | Do not interchange used bearing shells (mark positions) |

| q | Install new bearing shells for the cylinder block with the correct coloured markings → Fig. |

| q | Note location |

| q | Check radial clearance with Plastigage |

| 3 - | Chain sprocket |

| q | For oil pump chain |

| q | Renewing → Chapter |

| 4 - | Crankshaft |

| q | Axial clearance when new: 0.07 ... 0.23 mm; Wear limit: 0.30 mm |

| q | Check radial clearance with Plastigage |

| q | Do not rotate the crankshaft when checking the radial clearance |

| q | Radial clearance when new: 0.017 ... 0.037 mm; Wear limit 0.07 mm |

| q | Crankshaft dimensions → Chapter |

| 5 - | Bearing shell for bearing cap |

| q | Without oil groove |

| q | Do not interchange used bearing shells (mark positions) |

| q | The crankshaft bearing shells in the bearing caps are only supplied as spare parts with “yellow” coloured markings. |

| q | Note location |

| q | Check radial clearance with Plastigage |

| 6 - | 40 Nm + 90° (1/4 turn) further |

| q | Renew |

| q | For measuring radial clearance of crankshaft, tighten to 40 Nm but not further |

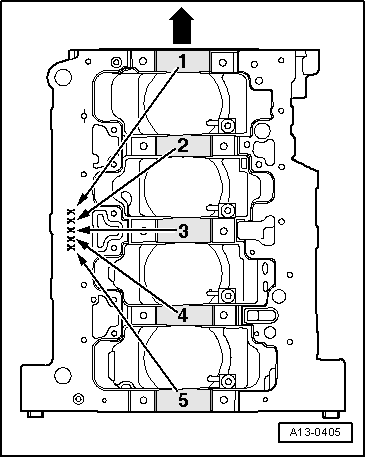

| 7 - | Bearing cap |

| q | Bearing cap 1: Pulley end |

| q | Installation position: Bearing shell retaining lugs (cylinder block/bearing cap) must be on the same side. |

| 8 - | 10 Nm + 90° (1/4 turn) further |

| q | Renew |

| q | Sender wheel must be renewed if bolts are loosened → Fig. |

| 9 - | Sender wheel |

| q | For engine speed sender -G28- |

| q | Can only be installed in one position (holes are off-set) |

| q | Sender wheel must be renewed if bolts are loosened |

| q | Removing and installing → Fig. |

| Component | Nm | ||||

| Sender wheel to crankshaft | 10 + 90° 1)2) | ||||

| |||||

Note

Note

|

|

| Letter on cylinder block | Colour coding of bearing | |

| B | = | Blue |

| G | = | Yellow |

| R | = | Red |

| W | = | White |

Note

Note

|