A3 Mk1

|

Removing and installing engine

Notes on removing

Note: Check whether a coded radio is installed as during the forthcoming work sequences the battery earth strap must be disconnected. Obtain radio code first if necessary.

=> Repair group 24; Servicing injection system; Removing and installing air cleaner |

|

|

Warning!

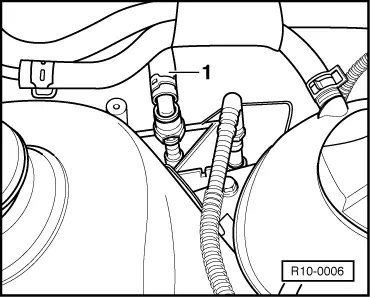

Fuel supply lines are under pressure! Before removing from hose connection wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection. |

|

|

=> General body repairs, exterior; Repair group 50; Front body; Noise insulation - Assembly overview Vehicles with drive unit protection plate

=> General body repairs, exterior; Repair group 50; Front body; Noise insulation - Assembly overview Continuation for all vehicles

=> 5-Speed manual gearbox 02T; Repair group 34; Servicing selector mechanism

=> 5-Speed manual gearbox 02T; Repair group 30; Servicing clutch mechanism Note: Clutch pedal must not be depressed.

Vehicles with air conditioner |

|

|

=> Heating, Air conditioning; Repair group 87; removing and installing compressor bracket

Continuation for all vehicles

|

|

|

|

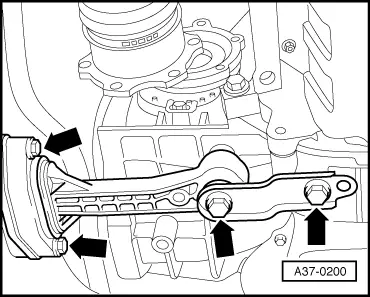

=> Running gear, axles, steering; Repair group 40; Removing and installing drive shaft

Pulley end: Flywheel end: Warning!

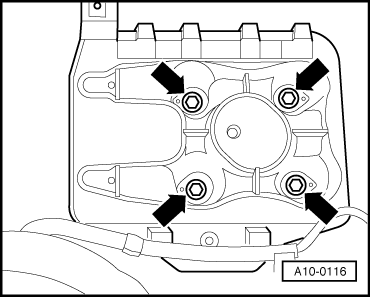

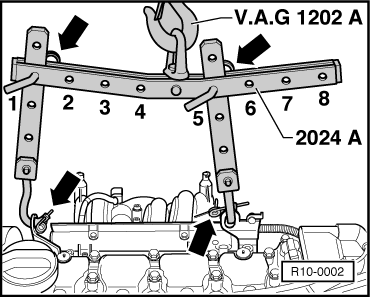

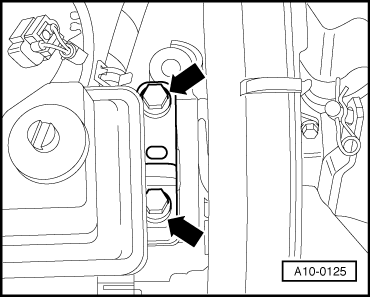

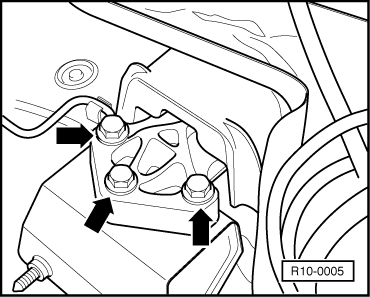

The hooks and locating pins must be secured with locking pins -arrows-. Notes:

|

|

|

|

|

|

Turn assembly slightly to left (engine forwards, gearbox rearwards) and lift out engine carefully. Note: When the assembly is lifted off, it must be carefully guided to prevent damage to the bodywork. |