A3 Mk1

|

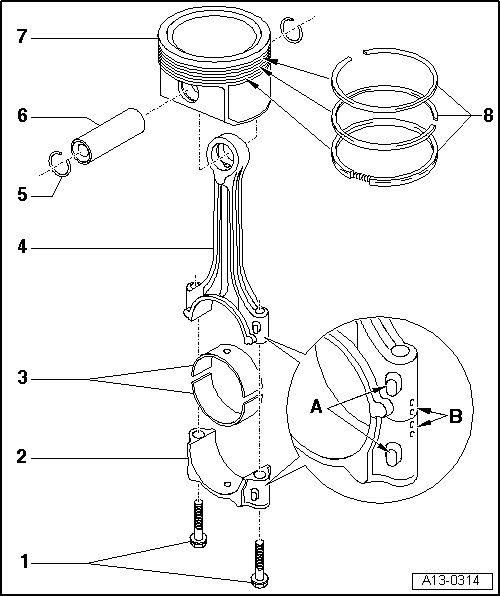

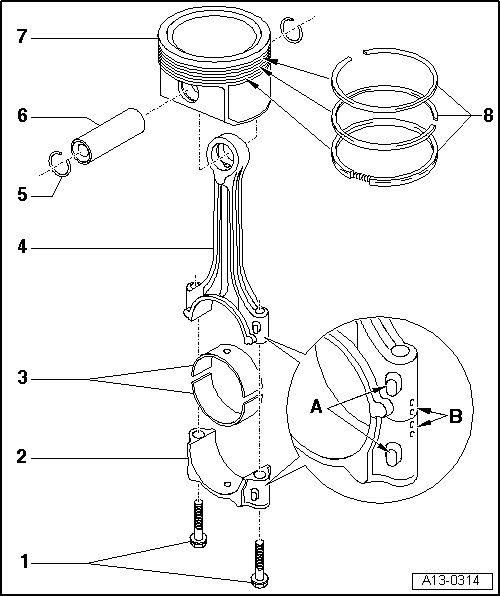

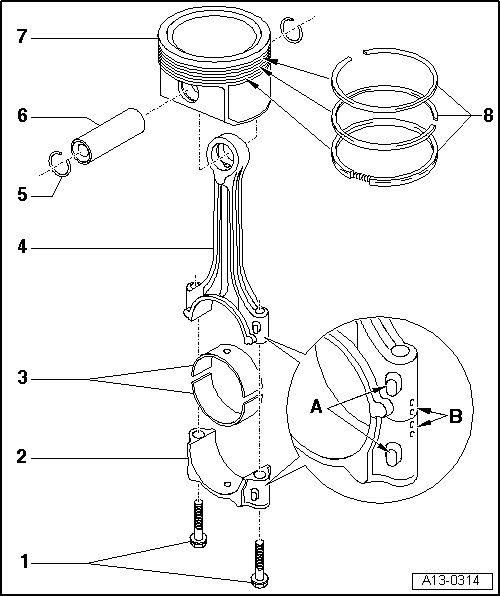

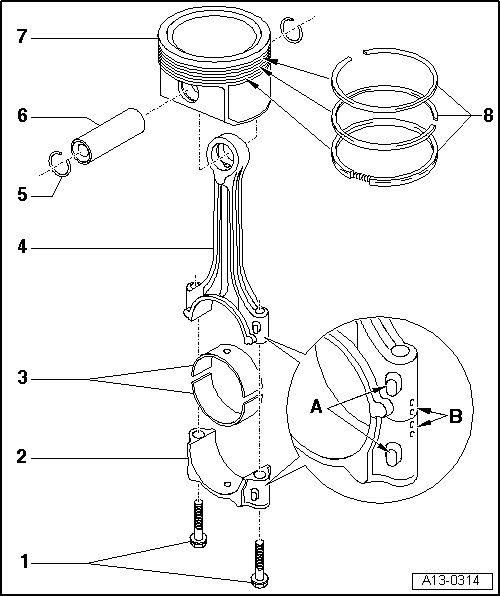

Dismantling and assembling pistons and conrods

Cracked-steel conrods

|

|

|

|

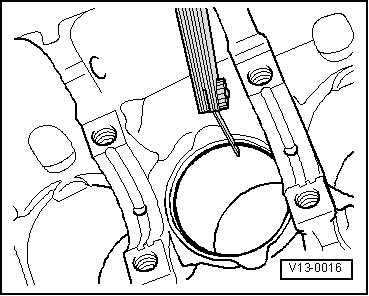

Note: Oil spray jet and oil pressure relief valve => Fig. 13-85

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

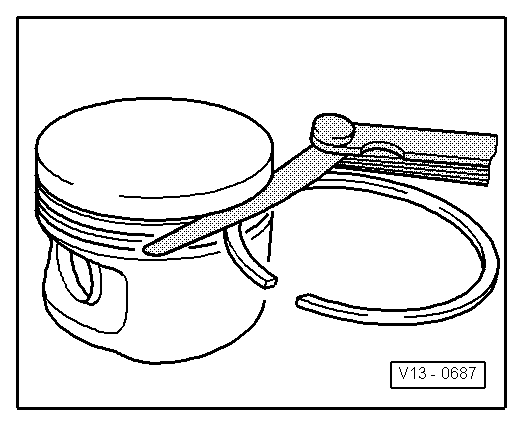

→ Fig. 2 Checking ring to groove clearance

|

|

|

|

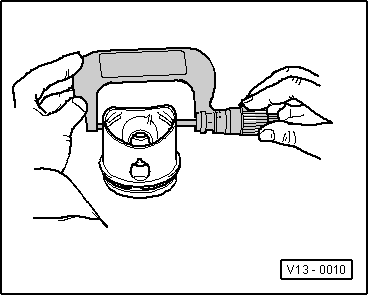

→ Fig. 3 Checking piston

|

|

|

|

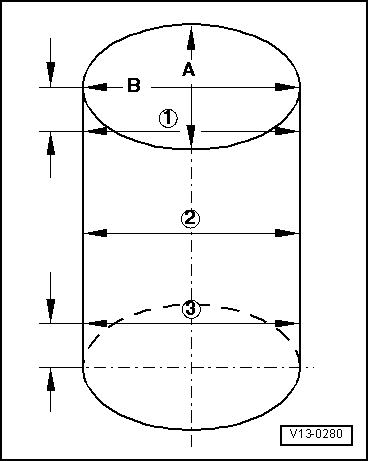

→ Fig. 4 Checking cylinder bores Special tools and workshop equipment required

|

|

|

|

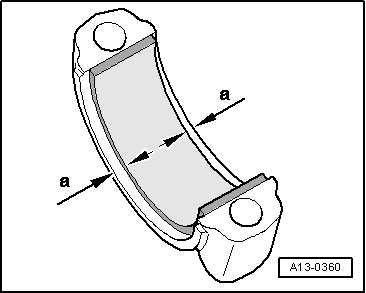

→ Fig.5 Bearing shell installation position with cracked-steel conrods

|

|

|

|

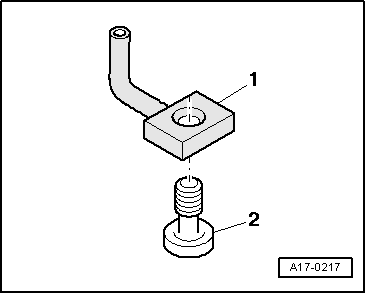

→ Fig.6 Oil spray jet and pressure relief valve

|