-

‒ → ... to the engine control unit for open circuits and short circuits to positive or earth.

|

|

|---|

|

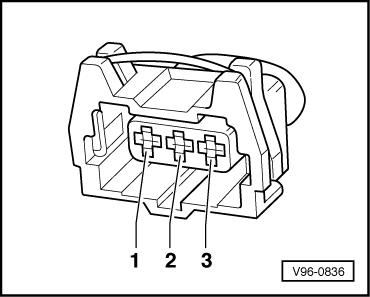

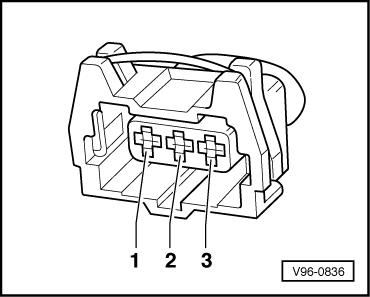

Contact on 3-pin connector for Hall sender

|

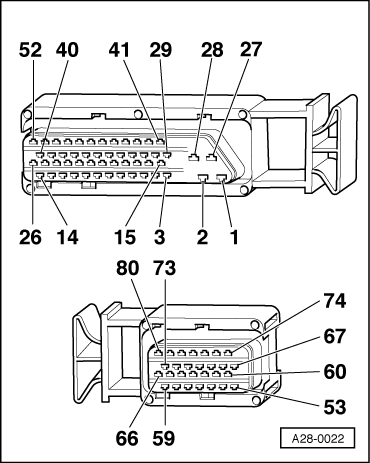

Contact on control unit connector

|

|

1 (positive)

|

62

|

|

2 (signal)

|

76

|

|

3 (earth)

|

67

|

-

‒ If all the test results so far have been OK but a fault related to the camshaft sensor (Hall sender) is displayed again after erasing the fault memory as a test measure, the cause may be as follows:

-

‒ Rotor aperture for Hall sender misaligned

-

‒ Unbolt Hall sender, then check to ensure that the rotor ring is correctly aligned on the camshaft. If incorrectly installed, the catch will be pressed flat when the securing screw is tightened.

-

‒ If the rotor ring is correctly aligned, check the position of the camshaft in relation to the crankshaft.

=> 4-Cylinder Engine, Mechanics; Repair Group 15; Cylinder head, valve gear; Removing and installing camshafts and camshaft adjustment

Note on signal testing with an oscilloscope:

The centre point of the window of the Hall sender must lie on the third downwards side of the engine speed signal after the reference mark gap.

|