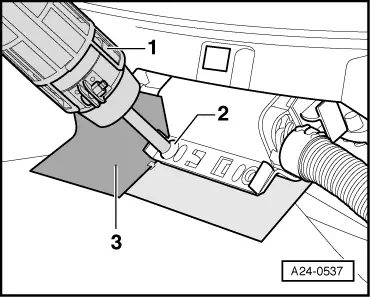

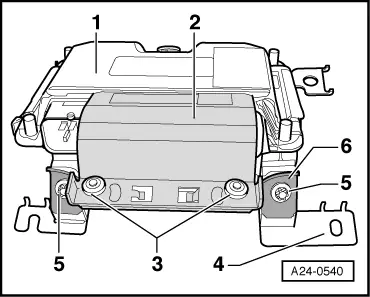

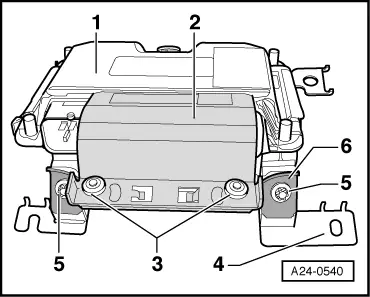

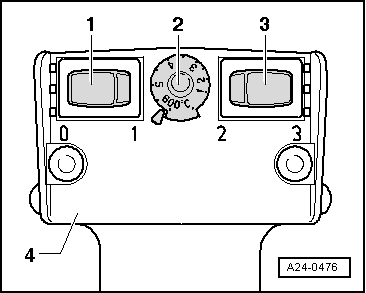

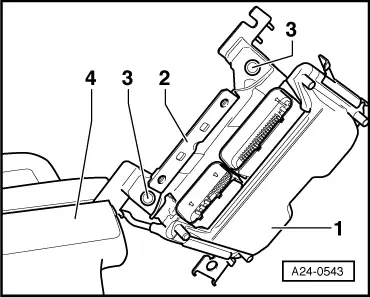

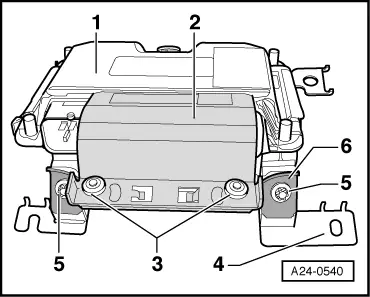

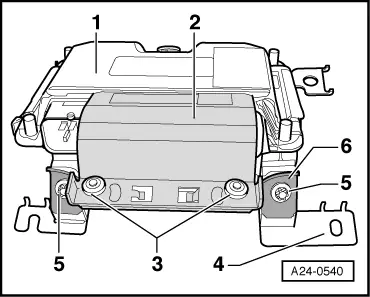

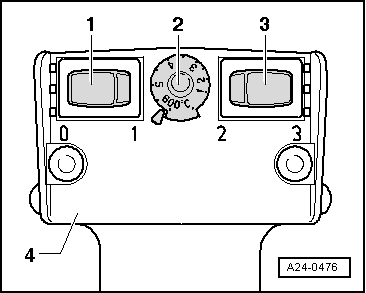

| To make it more difficult to pull out the engine control unit -1-, the locking element -2- is bolted onto the protective housing with the shear bolts -3-. |

| To make it even more difficult to screw out the shear bolts, the threads are coated with locking fluid. |

| –

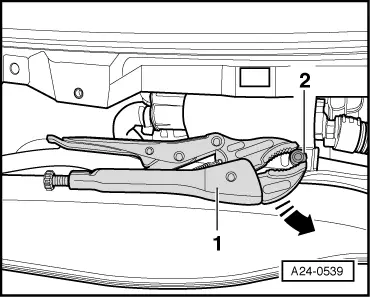

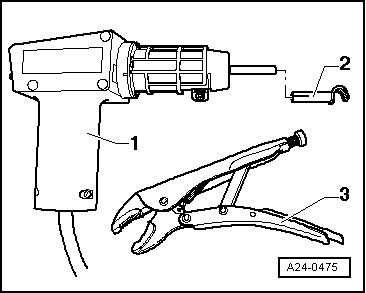

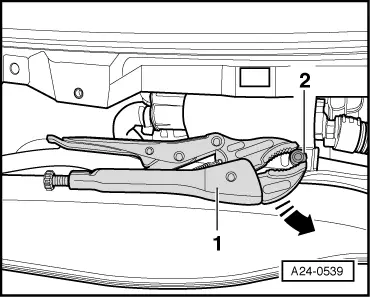

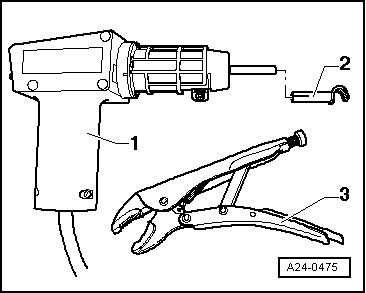

| Clamp the control unit in a vice |

| Installation is performed accordingly in the reverse sequence. |

| –

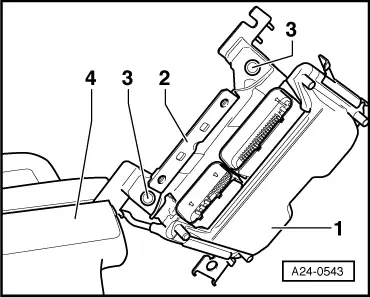

| The protective housing must always be re-attached to the engine control unit. |

| –

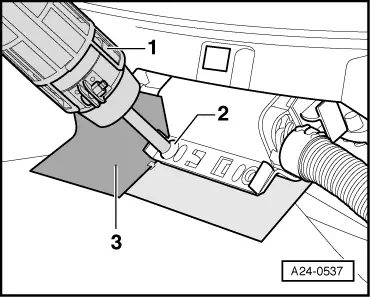

| Remove remnants of locking fluid from the tapped holes for the shear bolts. This can be done by using a thread tap. |

| –

| Always use new shear bolts. |

| –

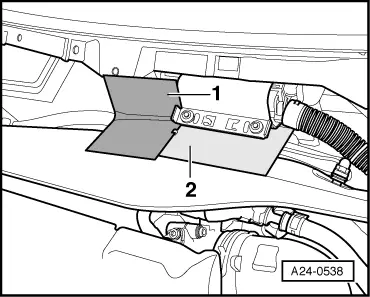

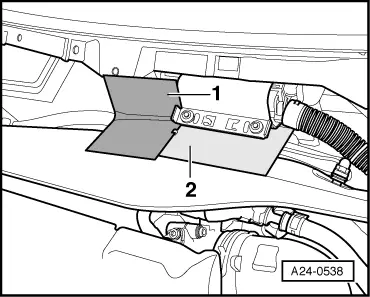

| Bend back the retainer tab of the mount. |

| The following operations must be performed after connecting the new engine control unit: |

| –

| Perform adaption of throttle valve module -J338- → Chapter. |

| –

| Perform adaption of kick-down function for vehicles with automatic gearbox → Chapter. |

| –

| The immobilizer must be enabled using vehicle diagnostic and service information system -VAS 5052-. |

| –

| In “Guided Fault Finding” mode, “Select type” menu, select the option “Remaining vehicles for online immobiliser interface” and follow the instructions in Guided Fault Finding. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note