A3 Mk1

|

|

|

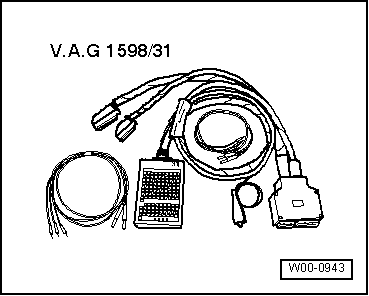

Special tools and workshop equipment required

Procedure

|

|

|

|

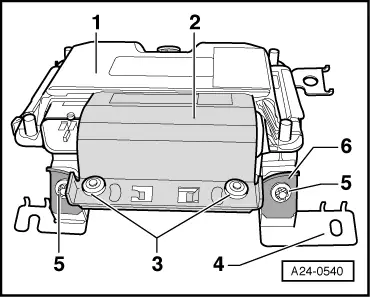

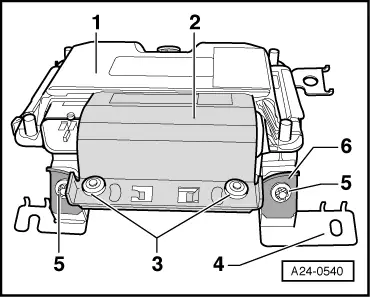

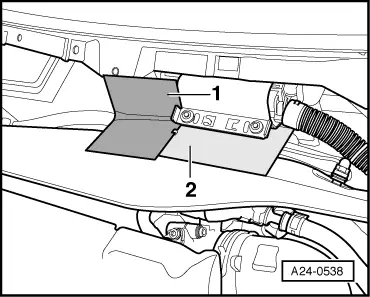

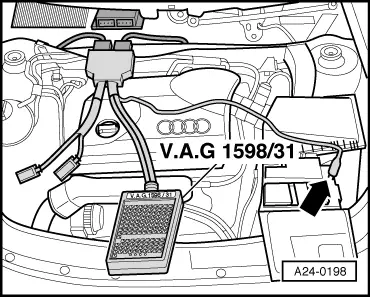

Note: Item -1- in the illustration shows the engine control unit with protective housing. |

|

|

|

→ To make access to the engine control unit connectors more difficult (anti-theft protection), the engine control unit -1- is fitted with a sheet-metal housing -4- via locking device -2- and shear bolts -3-. The thread of the shear bolts is coated with locking compound to make removal of the shear bolts especially difficult. If the connectors are to be unplugged from the engine control unit (e.g. to connect a test box), the locking device -2- must be detached from the sheet-metal housing. This procedure is described below. |

|

|

|

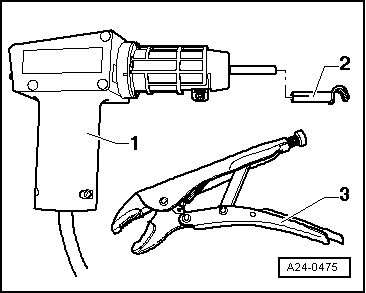

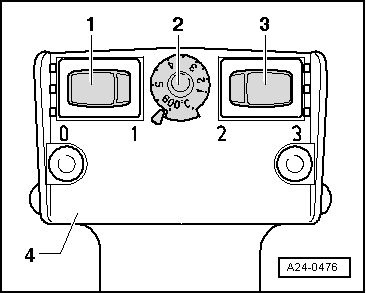

The following tools are needed:

Procedure: Important

The following steps must be followed exactly to prevent any damage (burning) to wiring, connectors, insulation and control units. Note the hot air blower operating instructions. |

|

|

|

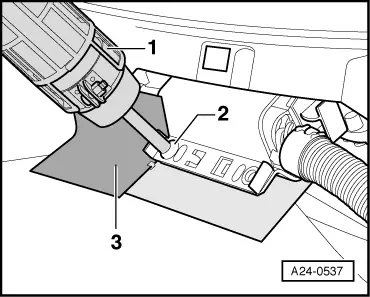

→ To prevent damage to wiring and connectors, make a screen using metal plates (Items -1- and -2-). |

|

|

Note: The bolt of the locking device is then heated with the hot air blower. This step diminishes the bonding effect of the locking compound on the thread of the shear bolts, and it is then easier to unscrew the shear bolts. Important

The shear bolts and sheet-metal housing components also become very hot when the thread of the locking device is being heated. Take care not to burn yourself on them. Ensure that as far as possible it is only the thread that is heated and none of the nearby components. If necessary, these should be covered. |

|

|

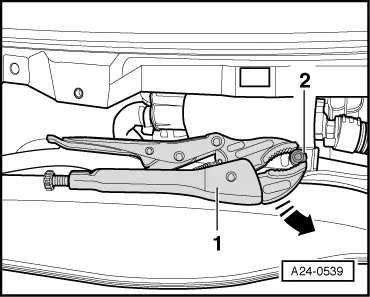

Note: Be especially careful here, because the control unit connectors are extremely near.

|

|

|

The procedure for the second shear bolt is exactly the same. Be especially careful here, because the control unit connectors are extremely near.

|

|

|

Perform the following operations after re-connection of engine control unit: Installation is carried out in reverse order to removal, and the sheet-metal housing (locking device) is refitted on the engine control unit. New shear bolts must be used.

|