A3 Mk1

|

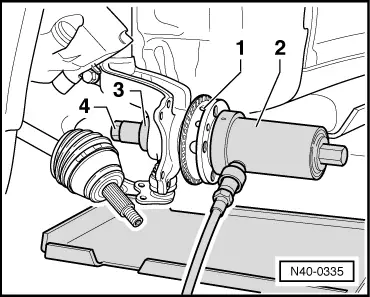

Wheel bearing housing

Replacing front wheel bearing with wheel bearing housing fitted

|

|

|

Sequence of operations

|

|

|

|

Four-wheel drive vehicles:

All models:

|

|

|

|

|

|

|

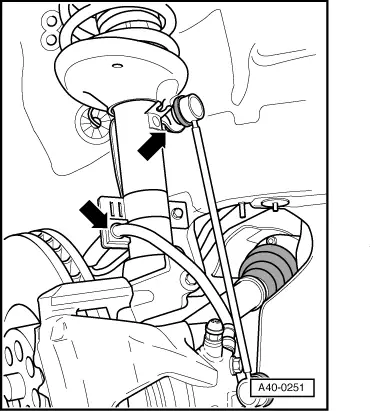

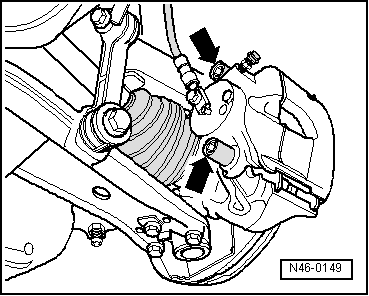

Vehicles with brake caliper FS 3:

Note: Brake hose/pipe is never to be twisted or kinked. |

|

|

|

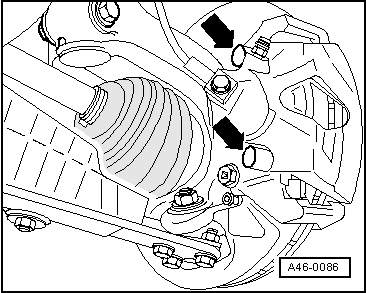

Vehicles with brake caliper FN 3:

|

|

|

Note: Brake hose/pipe is never to be twisted or kinked. All models:

|

|

|

|

Audi A3:

|

|

|

|

Audi S3:

|

|

|

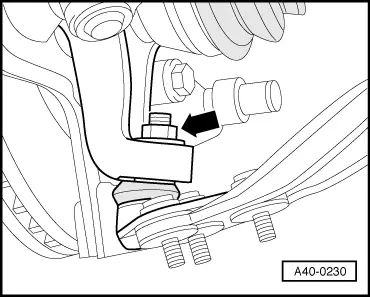

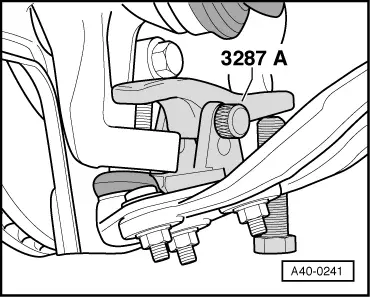

Note: Leave nut screwed several turns onto ball joint to protect thread.

Attention:

On pressing out, ball joint is abruptly released from wheel bearing housing and can be a source of danger. |

|

|

|

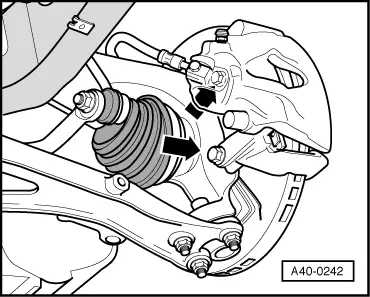

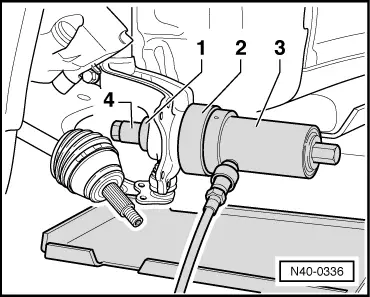

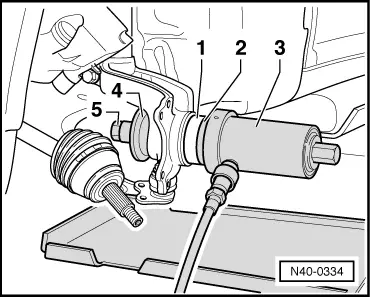

All models:

Note: Ensure adequate clearance when pressing out drive shaft.

Note: Failure to tie drive shaft in position would damage inner joint. |

|

|

|

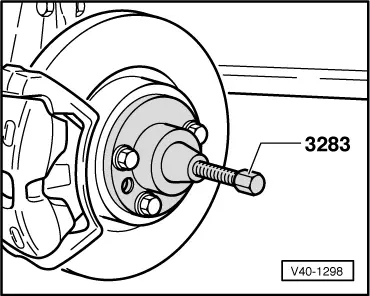

Pressing out wheel hub Attention:

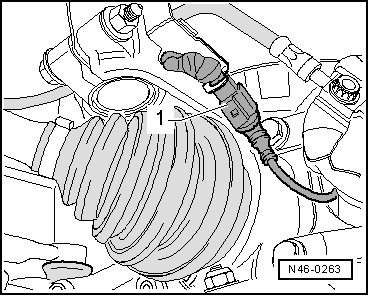

Place engine/gearbox lifter V.A.G 1383

|

|

|

|

Pressing out wheel bearing

|

|

|

|

Detaching bearing inner race from wheel hub

|

|

|

|

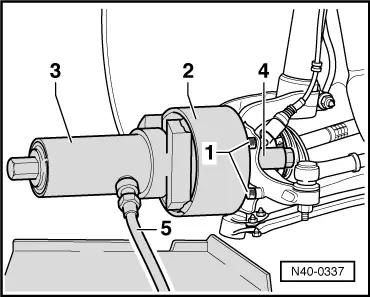

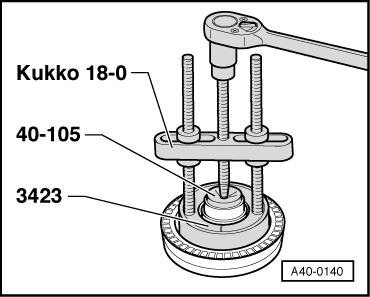

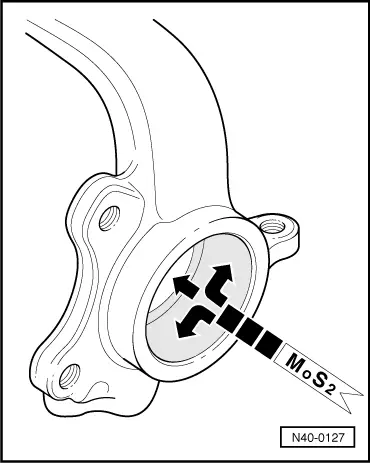

Pressing in wheel bearing

Note: A 3 g grease pad is included with the wheel bearing set. |

|

|

|

|

|||||||

|

Pressing in wheel hub

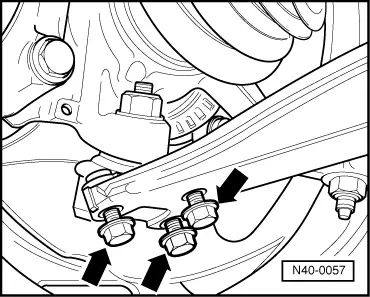

Perform further installation in reverse order, paying attention to the following:

=> Brake System; Repair Group 46 Tightening torque

1) Replace nut | |||||||