-

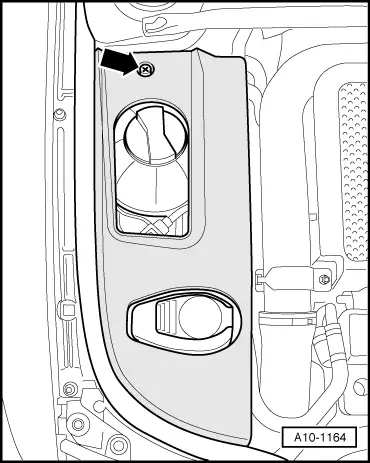

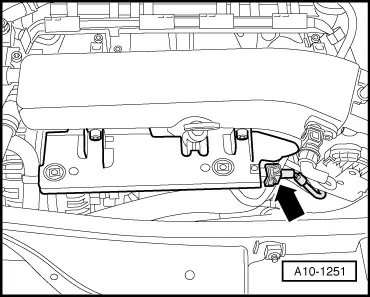

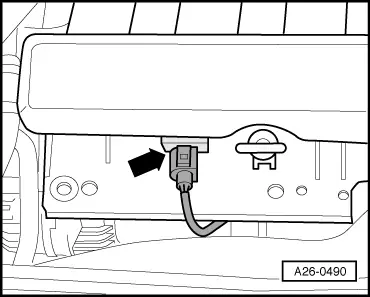

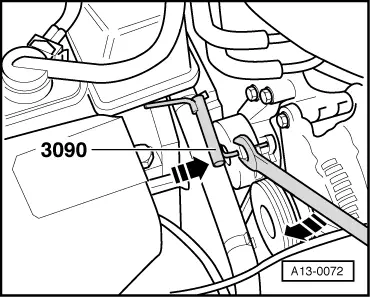

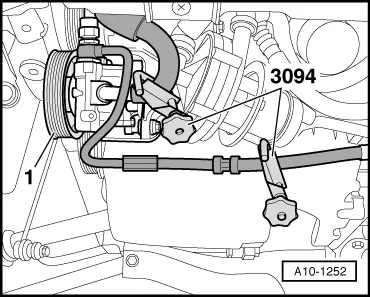

‒ → Unplug connector -1- at power-assisted steering pressure switch

-F88.

-

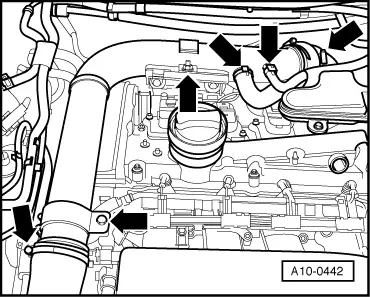

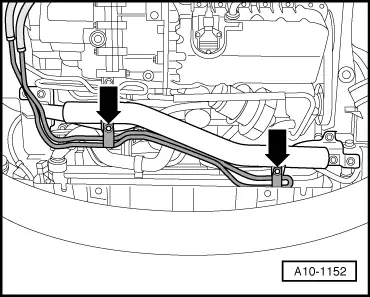

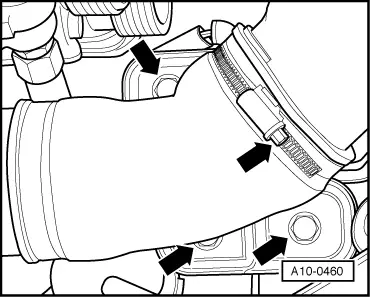

‒ Detach hydraulic hoses at vane pump.

-

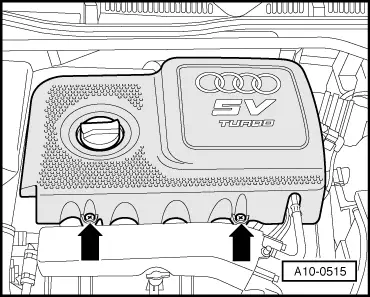

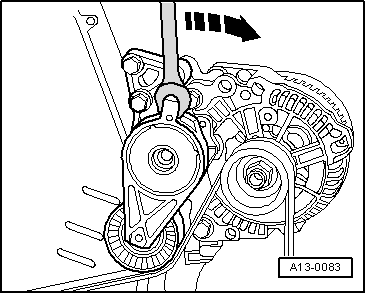

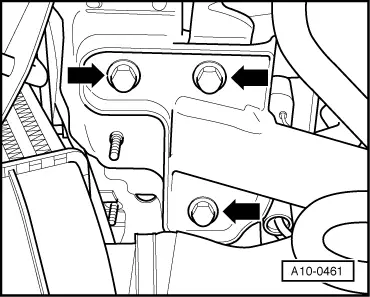

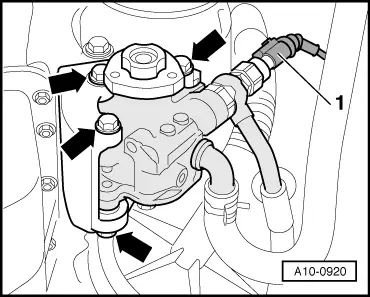

‒ Unscrew vane pump from bracket -arrows-.

Installing

Install in reverse order, paying attention to the following:

Notes:

-

◆ Replacement pumps are supplied without fluid fill. Prior to installation they are therefore to be filled with hydraulic fluid G 002 000 and cranked by hand to avoid the possibility of noise whilst driving or pump damage.

-

◆ Contact surfaces and threads on either side of vane pump must be free from paint.

-

◆ Hydraulic fluid drained off is not to be re-used.

-

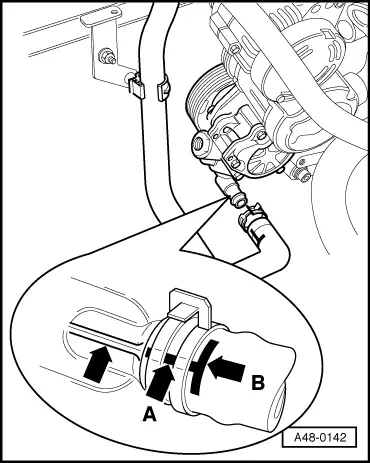

◆ Replace sealing rings.

|