| –

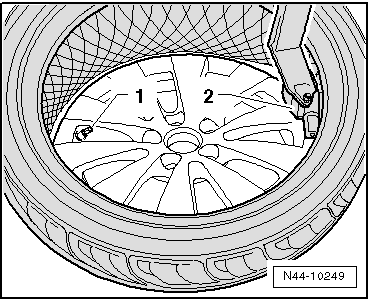

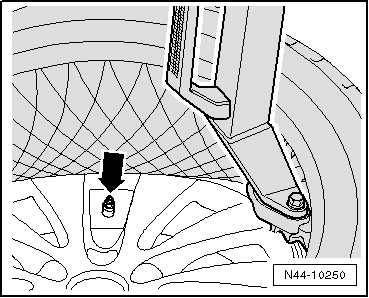

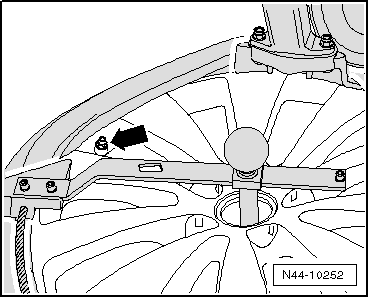

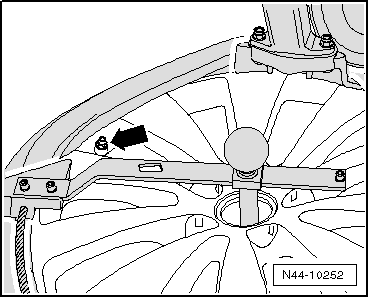

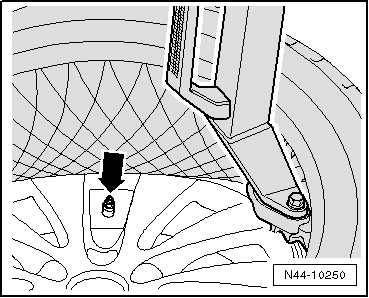

| Stop fitting upper bead before tyre valve/tyre pressure sensor-arrow- reaches tool; otherwise tyre pressure sensor will be damaged. |

| Tyre bead will now slip over wheel flange. Make sure that tyre fitting unit stops turning wheel before tyre valve/tyre pressure sensor-arrow- reaches head of fitting unit. |

| –

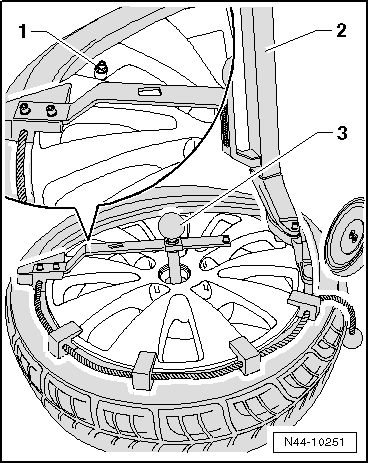

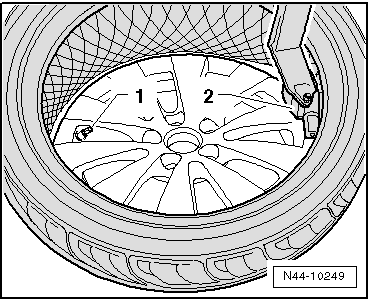

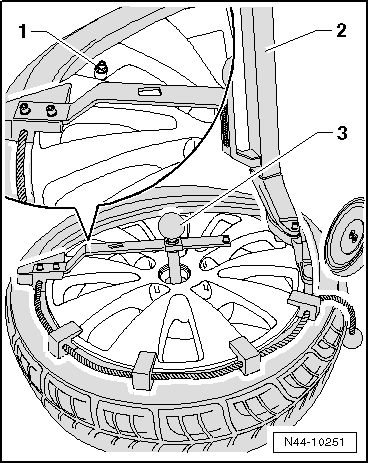

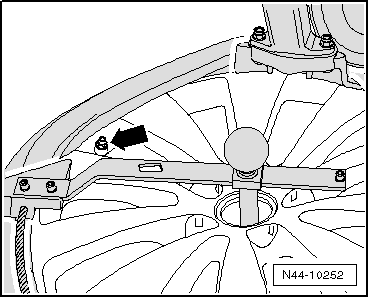

| Remove retainers from wheel flange. |

| –

| Inflate tyre to max. 3.3 bar (bead seating pressure). |

Caution | Do not continue inflating the tyre if the beads do not make full contact at the edge of the wheel. |

| The tyre or wheel will otherwise be damaged. |

|

| –

| If tyre beads do not make full contact at edge of wheel, release air from tyre, press off tyre bead again and apply another generous coating of tyre fitting lubricant to wheel flange. |

| –

| Inflate tyre to max. 3.3 bar (bead seating pressure). |

| –

| Once tyre beads have made proper contact with bead seats, increase inflation pressure to 4 bar to seat the tyre. |

| –

| Screw in a new valve core and inflate tyre to specified pressure. |

| –

| Then balance the wheel. |

| –

| Fit wheel to vehicle and tighten to specified torque. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note